Delivering clean cold and power

The brainchild of Peter Dearman, a lifelong inventor and engineer, the Dearman engine is a liquid-nitrogen-powered piston engine that produces clean cold and power. Peter was interested in an engine, and wider world, that didn’t rely on fossil fuels and so developed one in which the pistons are driven by the expansion of liquid nitrogen, or liquid air.

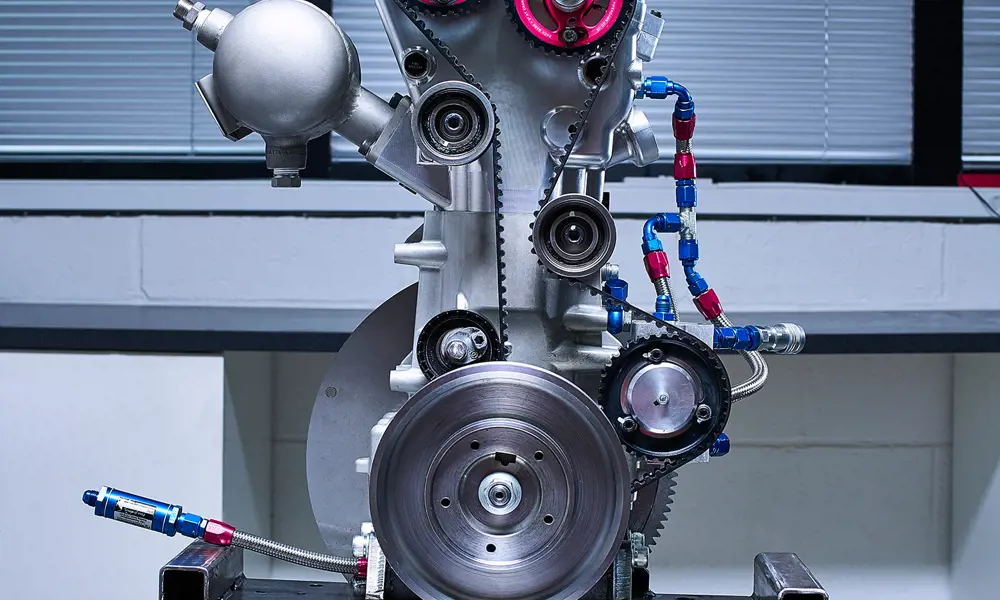

The engines are unique in using a heat exchange fluid (warm water) to fill the cylinder, which enables near-constant expansion when extremely cold nitrogen is introduced. The liquid-to-gas expansion ratio of nitrogen is 1:694 at 20°C so in an enclosed space, such as the cylinder, a huge amount of force is generated when liquid nitrogen is vaporised. The expansion forces the piston down and a mixture of gas and heat-exchange fluid is exhausted; the heat exchange fluid is reclaimed, reheated and reused while the liquid air is released back into the atmosphere.

One of the interesting things about a Dearman engine is that it produces potentially valuable cold as a by-product, rather than heat

One of the interesting things about a Dearman engine is that it produces potentially valuable cold as a by-product, rather than heat. The first application of this technology is to provide transport refrigeration units (TRUs). The power generated by the heat exchange supports ancillary systems, such as feed pumps and fans for air circulation, and drives a vapour compression refrigeration cycle that provides a third of the cooling needed. The other two-thirds of cooling are provided by compressed liquid nitrogen that is transferred to a vaporising heat exchanger to cool the chilled compartment.

The technology is environmentally friendly; as well as reusing the heat exchange fluid, the engines do not release any polluting emissions such as nitrous oxide, carbon dioxide or particulates. It is also cost effective and more efficient compared to existing TRUs that consume up to 20% of a vehicle’s overall fuel. Sainsbury’s is currently trialling the technology, during which it expects to save 1.6 tonnes of carbon dioxide, 37 kg of nitrogen oxide and 2 kg of particulate matter, compared to when using a diesel engine.

as well as reusing the heat exchange fluid, the engines do not release any polluting emissions such as nitrous oxide, carbon dioxide or particulates

During production, the engines can be engineered and configured to meet a range of different requirements for power output, efficiency and cooling capacity. Two variants of the engine are currently being developed: a simple single-cylinder engine that can be used for transport refrigeration units and auxiliary power and cooling units for buses; and a more complex multi-cylinder engine that produces more power and less surplus cold, which is being designed to act as a back-up generator for buildings and to form part of a waste-heat hybrid propulsion unit for trucks and buses.

For more information, see dearmanengine.com

Keep up-to-date with Ingenia for free

SubscribeRelated content

Mechanical

When will cars drive themselves?

There are many claims made about the progress of autonomous vehicles and their imminent arrival on UK roads. What progress has been made and how have measures that have already been implemented increased automation?

R&D investment makes good business sense

In just five years, Dr Ralf Speth FREng has presided over a revolution in design and manufacturing that has helped create a new family of engines and has overhauled Jaguar Land Rover (JLR) production facilities.

Bikes help improve skills and attitude

The Archway Project is an independently-funded scheme that is expanding its engineering-based programmes by providing BTEC certificates and diplomas. John Milton, the director of the project, explains what the charity does to help reduce anti-social behaviour and improve employment prospects.

High speed evolution

In December 2010, Eurostar International Ltd awarded a contract for 10 new high speed trains to Siemens. The company has used a system developed over decades to maximise the performance and passenger-carrying ability of its 320km/h trains.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95