Electric hairdryers

Most households probably have an electric hairdryer – a handheld device that we use to dry and style our hair. The small device uses various engineering elements to heat and blow air. Engineers must consider: electrical power consumption; materials for heating and cooling; the design, consumer appeal, structure, durability and weight; and the electronics for safe operation.

When a hairdryer is connected to a power socket and switched on, the electricity powers a heating element and an electric motor, which operates a fan in the dryer. The heating element converts the electrical energy into heat of up to 2,000 watts. This process is known as resistive heating and is used in other household appliances, like the electric kettle and toaster.

Hairdryers often have a ceramic or polymer frame and casing. Polymers are lightweight plastic materials with a limitless range of colours and significant degrees of strength. They are also good thermal and electrical insulators. They protect the internal components of the hairdryer and users from burns and electric shock. Polymer casing also allows for injection moulding; a fast manufacturing process used to produce large numbers of identical items of plastic with compartments that interlock with snap-fasteners for easy assembly.

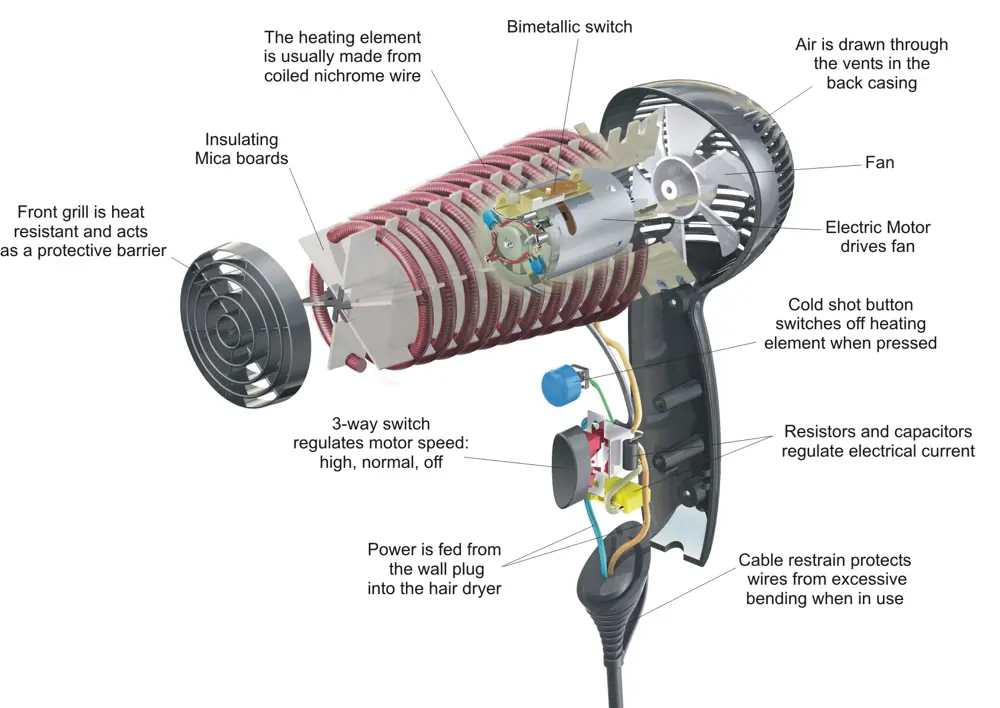

Diagram of a traditional hairdryer © Anthony Samboer

The electrical motor and fan are at the back of the casing in an area called the air inlet, which is covered with a fine mesh screen to prevent objects accidentally getting caught in the fan blades. At the opposite end is the air outlet, with a heat resistant and protective front grill, where the nozzle is attached. The heating element, which sits in between the air inlet and outlet, is a conductor usually made of coiled nichrome wire, typically 30 centimetres in length. The wire looks like a coiled spring and is wrapped around an insulating board so that the entire heating element is only a few centimetres long. This insulating board is usually made of mica, a mineral found in India, Belgium, Brazil, and China, which can withstand extreme temperatures. Two flat pieces of mica form a three-dimensional X that has notches cut in the edges to keep the wrapped coiled nichrome wires in place, allowing air to flow through the long barrel casing.

An electrical circuit connects the ends of the heating element’s coiled wires to the power. The three-way switch in the handle controls the power to the motor and heating element, allowing control of the airflow and temperature. Sensors keep the hairdryer at a comfortable temperature and detect overheating. A cut-off switch made from a bimetallic strip shuts the unit down when necessary, preventing the hairdryer from exceeding 60°C. A thermal fuse built into the circuit provides another layer of safety, instantly breaking the circuit when the temperature exceeds the limit. The ground-fault circuit interrupter is built into the hairdryer to prevent electrocution. It senses how much current is flowing through the circuit and can shut it off if it detects a leak or a short circuit.

The electric fan rotates and blows air across the heating element. As the air passes through the heating element, the air is warmed and heated up. The hot air exits the dryer through a nozzle, to concentrate the air flow. When it reaches wet hair, it absorbs the moisture and dries the hair.

Contributors

Dr Ozak Esu is an ambassador for the Queen Elizabeth Prize for Engineering (QEPrize). She is a chartered electronic and electrical engineer and a member of the Institution of Engineering and Technology. Follow her on X: @esu_o

Keep up-to-date with Ingenia for free

SubscribeRelated content

Design & manufacturing

Super cool(er)

Welsh startup Sure Chill has developed a cooler that uses the properties of water to keep its contents cool for around 10 days without electricity. This is ideal for storing items such as vaccines where electricity sources are unreliable.

R&D investment makes good business sense

In just five years, Dr Ralf Speth FREng has presided over a revolution in design and manufacturing that has helped create a new family of engines and has overhauled Jaguar Land Rover (JLR) production facilities.

Steel can arise from the ashes of coal

Thousands of people were laid off in the UK steel industry in 2015 and there are pessimistic future forecasts. Professor Sridhar Seetharaman of the Warwick Manufacturing Group argues that smaller, flexible steel mills implementing new technology would better cope with fluctuating global trends.

Integrating metrology in business and academe

Professor Jane Jiang’s interest in measuring began when she worked on a bus production line in China. She found that the best way to improve quality, consistency and productivity was through metrology, the science of measurement. Today, she runs the UK’s largest metrology research group.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95