Farming straight up

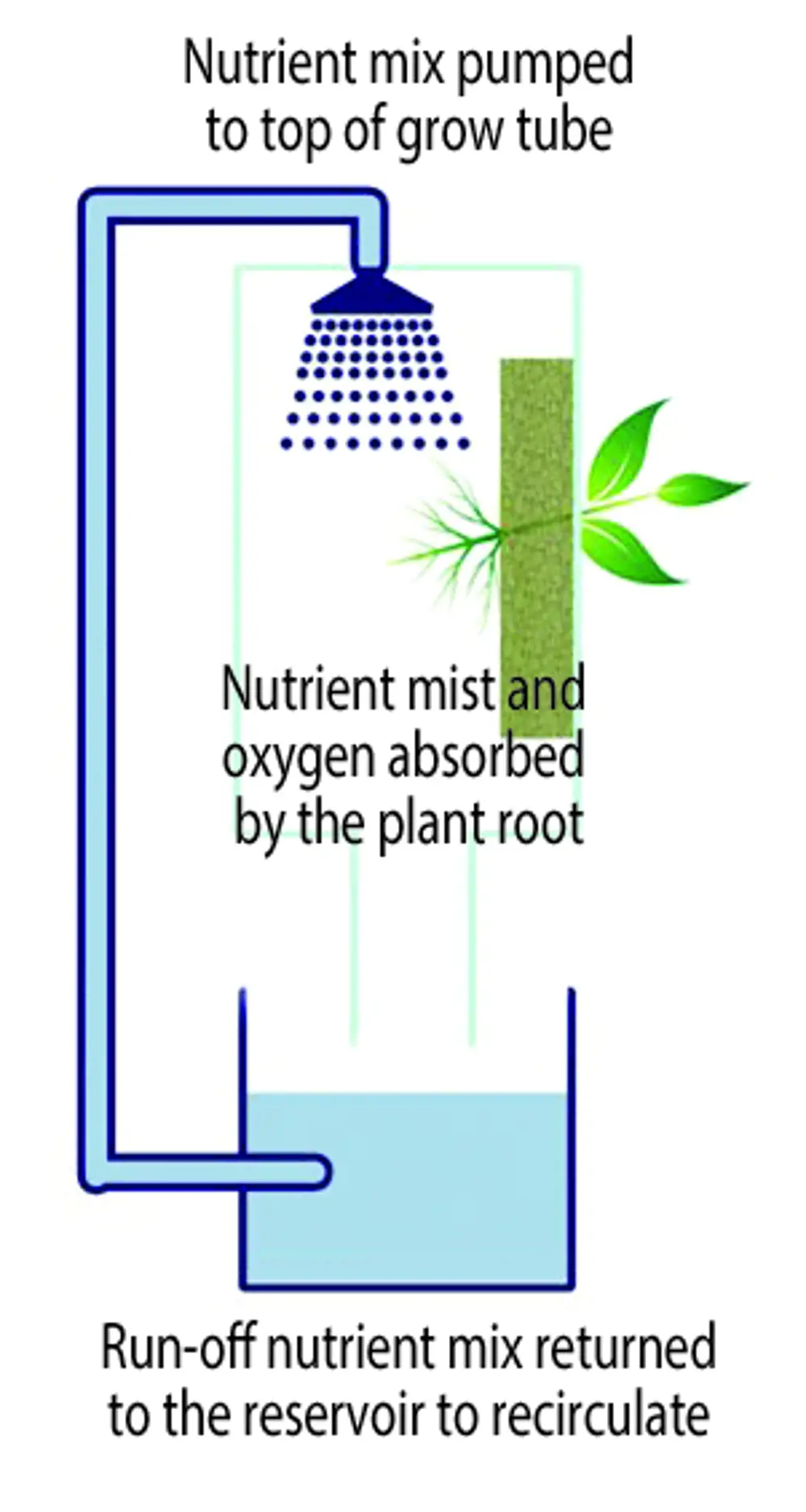

In Aponic’s system, nutrients are sprayed directly onto the roots of plants. Excess water and nutrients are recaptured and recycled

Suffolk manufacturer Aponic, led by former aviation engineer Jason Hawkins-Row, has developed a food-growing system based on the same principles as hydroponics. Its method allows plants to be grown in vertical columns with the roots in air, which is more efficient and sustainable than using water.

Jason’s interest in natural eco-systems began when he became involved in projects that looked at natural methods of rainwater recycling and water purification. The inspiration for the growing system came when his fruit and vegetables were stolen from his allotment, which encouraged him to ensure that his food was grown securely.

The company’s aeroponic system holds plants by the roots inside vertical growing tubes filled with air. Every 20 minutes, a mixture of water and nutrients is automatically sprayed onto the roots for 10 to 15 seconds. The overall spraying time for the plants totals just 18 minutes each day. As it uses so little power, the system can be run ‘off grid’ by electricity generated by solar or wind, meaning it can easily be used in developing countries or in places with an unreliable energy supply.

The nutrient and water mix is recycled through the tubes and fully used in the growing process, which reduces water usage by an average of 90% compared to traditional growing methods. Aeroponic systems have even been used by NASA, as they can successfully produce food in both zero and artificial gravity environments.

This type of ‘vertical farming’ allows crops to be produced on smaller land area: 12 or more plants can be grown in the same space it would take to grow one plant in soil. Systems can be placed in greenhouses, barns and outbuildings, and vertical farming is popular in urban areas, such as industrial units and abandoned buildings.

Planting, tending and harvesting are easier for operators, who can work comfortably in a standing position. Removing soil from the equation means that there are no slugs, soil pathogens or weeds, reducing the cost further by removing the need for weed-killers. The pH of the water that the plants receive can be controlled, and the nutrients can be carefully adapted to the different stages of growth, so that growing conditions are optimal. If the system is used indoors, then temperature, humidity and light can be controlled, and matched with a nutrient regime and CO2 injection regardless of season, environmental conditions or geographical location. This has implications for seasonal crops, and means that commercial farmers can consistently produce perfect crops to a reliable timescale.

As part of the NIAB (National Institute of Agricultural Botany) Innovation Hub, Aponic is developing collaborative relationships with universities and research facilities to deliver the growing systems and training in developing countries where there are problems such as limited infrastructure, water shortages or bad soil.

As the UK currently imports 48% of its fresh food, Aponic hopes to reduce the need for imports and increase sustainable food security. It has recently developed modularised freight units to be stacked in barns or installed in growing containers to produce low-input, high-value output modular farms that are being sent all over the world. It is also working with large tech companies to develop a remote control and monitoring system to develop completely traceable produce.

***

This article has been adapted from "Farming straight up", which originally appeared in the print edition of Ingenia 71 (June 2017)

Keep up-to-date with Ingenia for free

SubscribeRelated content

Food & agriculture

Precision farming

Technologies such as global positioning systems and guided vehicles are being developed to create an era of precision farming. Professor Richard Godwin FREng explains how these initiatives can combine accuracy and control of field operations leading to increased efficiency and yields.

What role for biofuels in low-carbon UK transport?

Biofuels have a role to play in meeting the UK’s climate change commitments. Sustainable Chemical Engineering Professor Adisa Azapagic FREng sets out why biofuels made from wastes and by-products in different sectors are particularly important to these efforts.

The automation of dairy farms

Robotic milking is not a new innovation, but the systems are increasingly being adopted by UK dairy farms. Science writer and broadcaster Geoff Watts learned from John Baines, Technical Director at Fullwood, how these systems are being engineered to do more than just milk cows.

Vertical farming for future growth

More of us live in cities than ever before and the global population is estimated to reach 11.2 billion by 2100, creating mounting challenges for agriculture. Growth Solutions grow produce under lights in vertically stacked towers to help meet growing demand for food.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95