Lasers to change the world

With “a mission to harness the power of light to change the world” no one would accuse M Squared of lacking ambition. Unlike a lot of sales pitches however, the company can point to numerous uses of its lasers that support its vision. Playing a central role in tackling climate change, SolsTiS was used to calibrate Tropomi, the spectrometer onboard the European Space Agency’s (ESA) Sentinel 5P satellite that observes and maps critical atmospheric pollutants, including nitrogen dioxide, ozone, formaldehyde, sulphur dioxide, methane and carbon monoxide. In healthcare, the lasers allow the non-invasive study of cancers and degenerative diseases such as dementia, motor neurone disease and Parkinson’s. Lasers are used for research in numerous scientific fields and industries, ranging from quantum technologies and semiconductors to chemical sensing and biophotonics and the SolsTiS is used by used by over 200 organisations in 30 countries.

It was, though, the engineering inside the laser that appealed to the judges of the 2019 MacRobert Award. Lasers tend to be sensitive devices that operate at nanometre dimensions. When researchers are working on, for example, breath analysis, the last thing they want to do is to have to retune a laser when it gets bumped. Before SolsTiS, scientific lasers were largely experimental in themselves.

It takes clever engineering design to create laser systems that can deliver “the highest purity light yet produced anywhere in the world”. M Squared’s SolsTiS system stands out because of its precision, compactness, ruggedness, reliability and turnkey operation. SolsTiS delivers a step-change in continuous-wave laser technology, delivering single mode laser light with an ultranarrow linewidth. The system is also fully automated and widely tunable, connected to the internet and operated via a webpage. All of this sits in a completely sealed unit that needs no alignment by the user.

The SolsTiS laser is used in the world’s most accurate clock, and could open the way to quantum computing © M Squared

From research to product

M Squared had its origins in Dr Graeme Malcolm OBE FRSE’s PhD project on compact lasers at the University of Strathclyde. The university has a long reputation as a leading centre of research and innovation in laser technology and optoelectronics and was at the centre of Scotland’s optoelectronics sector. In 1992, Malcolm, along with Dr Gareth Maker, set up Microlase Optical Systems to turn their research into usable products. The two did not have to wait long for orders to come in. Indeed, they set up the business partly because, as research students, they were already supplying systems to other research groups.

As Malcolm put it at the time, “We were effectively pioneering the research we were doing at the University of Strathclyde then. Older generations of devices were six-foot long, highly complex and you needed a PhD to operate them. They needed 50 kW of power, were the size of a filing cabinet, and required gallons of water to keep them cool.”

Equipment like that wasn’t the sort of thing that anyone but a laser researcher would deploy as standard kit in their academic laboratory, let alone in industry. Malcolm and Maker wanted to develop a self-contained diodepumped laser that was smaller than a shoebox – you could just plug it into the mains and light would come out.

In 1999, the global laser businesses Coherent Inc. bought up Microlase Optical Systems and Malcolm became head of Coherent Scotland. This gave Malcolm and Maker the resources needed to develop the business. They could move on from selling lasers to laser scientists and begin the laser’s transformation into a usable and reliable device that non-specialist engineers could use almost as routine components in complete systems for whatever applications they had in mind that needed a very pure source of coherent light. They also moved into new wavelengths, and very short light pulse lasers, to broaden the range of applications, such as biomedical imaging.

In 2006, Malcolm and Maker left Coherent Scotland to set up another company to develop a laser system based on research at Strathclyde and elsewhere. The new company was M Squared, which gets its name from the two founders and the M2 parameter known as a laser’s ‘beam quality factor’. The idea was to produce a compact and totally automated version of the single frequency Ti:Sapphire laser, the optical ‘engine’ inside the SolsTiS system.

Challenges overcome

As well as active and passive dimensional control in the nanometre range, the engineers had to isolate the optical components from vibration created by the circulated water cooling. The design of the hardware also had to isolate the optical elements from temperature variations and physical impact.

SolsTiS also required optical innovations to fit a long optical path into a small space, using a ‘bow-tie’ arrangement of four mirrors. Additional optical elements in the light path refine the light output so that the laser output has an extremely narrow linewidth – the narrowest of any commercial system – and is single mode across its whole tuning range. To do this, the engineers not only had to devise their own approach to mounting the optical components to maintain the stability of the system, but also develop precision adjusting elements and control software to compensate for uncontrollable movements as well as enabling wavelength tuning. It was, says David Delpy, MacRobert Award judge, “a truly impressive piece of kit operating at unprecedented levels of accuracy and reliability. It takes an enormous amount of engineering to get the optical system right to enable it to do this”.

Much of the innovation was in the application of novel physics and mechanical engineering to create continuous-wave and tunable laser light on an unparalleled ‘small’ scale. The parts were designed from scratch. Beneath these engineering achievements sits an enormous number of careful design measures, such as the use of a minimum number of easily-cleanable materials to control thermal expansion and that do not absorb or emit gases that could escape into the cavity and disturb the laser’s output. Even the laser crystal light source required careful engineering, with a unique slab design of optical material, chosen to deliver the required tuning range, and held rigidly in a stress-free mount. The company holds more than 400 patents on the innovations that went into the system and the areas in which it is used.

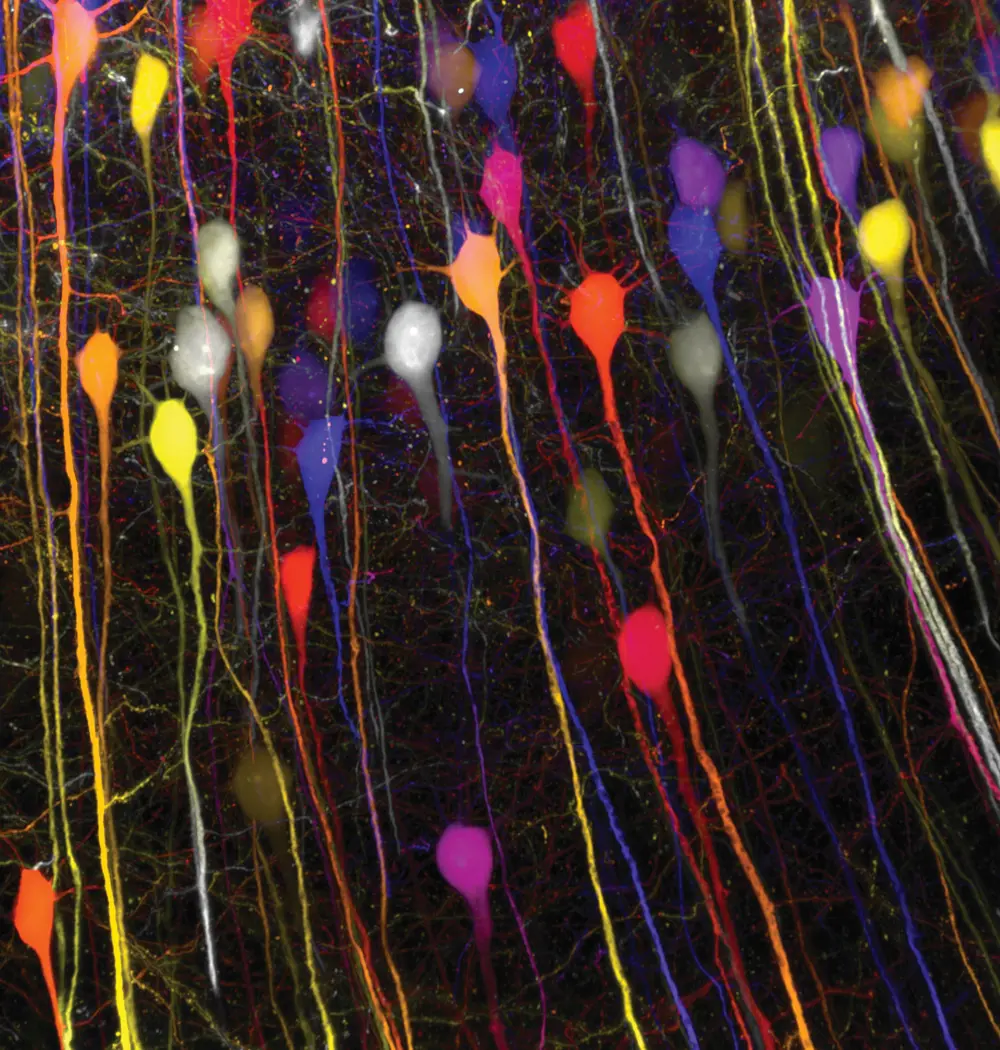

The engineering behind SolsTiS supported the development of the Aurora light sheet fluorescence microscope, here showing an optically cleared mouse brain expressing thy1-GFP Actin, maximum intensity projected using a coloured height map © Dr Anthony Vernon and Robert Chesters, King’s College London

Applications space and time

Beyond being a finalist in this year’s MacRobert awards, the success of M Squared’s engineering shows in the range of applications for the SolsTiS lasers. At one stage, atomic clocks were a big market for the lasers. The US National Institute for Standards and Technology (NIST) used them in the world’s most accurate clocks, giving an accuracy of one part in 1018, equivalent to a second in the lifetime of the universe, says Malcolm. Atomic clocks are already used in areas ranging from financial trading to navigation.

In their assessment of the laser’s clear societal benefits, the judges of the MacRobert Award also noted its use in the accurate calibration of instruments for Earth observation satellites, allowing observations of polluted areas on earth from space, accurate to a five-kilometre square. As the judges put it, “concentrations of formaldehyde, nitrogen oxides, methane and carbon monoxide can now be monitored from space for the first time.” In fact, M Squared was approached by the ESA with an emergency request – design a solution for monitoring CO2 from space – and the SolsTiS delivered. The lasers were used to calibrate the Trompomi telescope on the ESA satellite Sentinel 5P before launch, the first industrial laser for earth observation.

One sign of the commercial success, and promise, of the SolsTiS technology is the growing market for the laser and its associated systems. What started off as a musthave instrument for university physics laboratories and national laboratories has moved on. Industrial applications now make up the largest market. Semiconductor applications that require laser cutting of stencils for sub-micron-sized components, using laser-based machine tools, have been designed in collaboration with M Squared.

With Aurora, life scientists can accurately image large structures at cellular resolution, measurements that are fundamental to modern biological understanding

M Squared has also branched out of the world of physics and engineering into the life sciences. For example, the engineering behind SolsTiS also supported development of the Aurora light sheet fluorescence microscope. The company designed this system for researchers working in fields such as neuroscience, developmental biology, cancer biology, regenerative medicine and other bioscience disciplines. With Aurora, life scientists can accurately image large structures at cellular resolution, measurements that are fundamental to modern biological understanding. The technology also enables life science imaging at individual cell level, including neurons in the brain.

The company says that its lasers have enabled breakthroughs in areas as diverse as dementia research cancer diagnosis and whiskey maturation. In 2015, M Squared opened a specialised biophotonics division, M Squared Life, on the Surrey Research Park.

Quantum accelerometer for navigation

🧭 A commercial quantum navigation system without the need for back-and-forth satellite communications

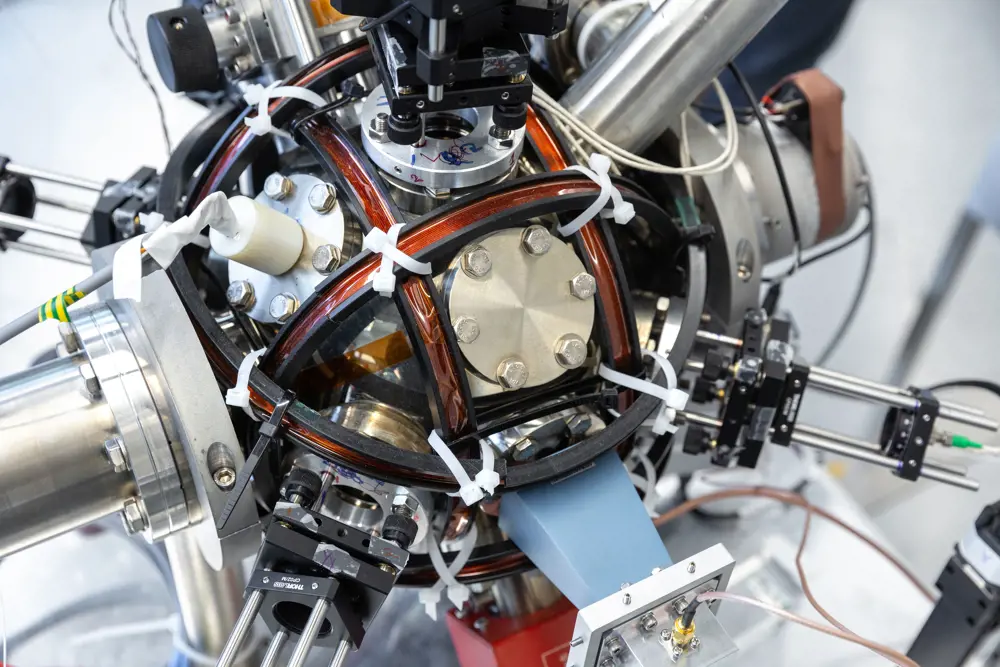

One development in the rapidly rising realm of quantum technology is M Squared’s work with Imperial College on the UK’s first commercial quantum accelerometer for navigation. The accelerometer uses quantum interference of matter waves to measure horizontal accelerations with ultra-high accuracy. It identifies its starting location, and precisely measures acceleration from there. As the company puts it, “The purpose of this is to navigate ships and submarines, and perhaps other vehicles in the future.”

The global navigation satellite system (GNSS) that underpins many location systems is susceptible to disruption or denial, either deliberate or natural. Estimates suggest that interfering with GNSS for a just five days could cause £5.2 billion of economic damage to the UK alone. “Quantum sensors, including our accelerometer, offer a new way to achieve accurate navigation without the need to send communications back and forth to satellites,” says M Squared.

M Squared and Imperial College are developing a commercial quantum navigation system. Their aim is to achieve the highest possible sensitivity and to provide accurate positioning, even over long journeys. Their quantum accelerometer recently showed a positional accuracy within 2 kilometres after one month’s use, a substantial improvement in state of the art accelerometry.

Imperial College London and M Squared has produced the world’s first transportable, stand alone quantum accelerometer incorporating the SolsTiS system © Thomas Angus, Imperial College London

Quantum technology

More recently M Squared has moved into another area where research meets engineering, quantum technology. M Squared describes SolsTiS as “the backbone of many quantum technology systems and experiments”. The laser’s ultra-pure light and low noise makes it “the ideal tool for quantum experimentation, where excess noise can easily destroy the subtle effects that quantum technologies seek to exploit.”

The team maintains that SolsTiS is “the de facto standard laser system used in the development of quantum technologies and experiments”. It is also used extensively in several approaches to quantum computing, including leading research at Oxford, Sussex and Innsbruck universities. SolsTiS is also responsible for many new advances in quantum sensing. M Squared likes to describe SolsTiS as the backbone ‘engine’ behind much of its work, for example, on the UK’s first commercial quantum gravimeter to detect underground objects and a quantum accelerometer for GPS-free navigation. The quantum accelerometer uses SolsTiS to suspend and release atom clouds.

One sign of the expectations for quantum technology, and the company’s commitment to the area, was the recent announcement that M Squared has opened a new quantum research facility in Glasgow. Hosted by the University of Strathclyde, the new quantum research centre is in the university’s Inovo building in Glasgow City Innovation District. At the time of the announcement, Derek Mackay, Scotland’s Economy Secretary said: “Our economic development agency Scottish Enterprise recently awarded a £2.9 million R&D grant to M Squared to help accelerate their cutting-edge research… [It] will support 24 new jobs, help realise Scotland’s quantum potential, and enhance our ability to compete globally.” Also commenting on the announcement, Malcolm said “We are on the verge of a second quantum revolution whereby the counter-intuitive behaviour of physics at the atomic scale will be harnessed to create the defining technological advances of the future.”

these developments in quantum technology “will most likely underpin the next transformative large-scale economic transition”

M Squared has grown to have a turnover of more than £20 million a year and employs more than 100 people, most of them in technical roles. The business is doubling in size every two or three years, fuelled by reinvesting 10% to 20% of its revenue in R&D. SolsTiS accounts for 85% of the company’s sales.

“The huge promises of quantum technologies are already starting to become tangible,” says Malcolm. In the MacRobert Award judges’ view, these developments in quantum technology “will most likely underpin the next transformative large-scale economic transition”. It is, then, perhaps no surprise that one magazine described M Squared as the company that “sells the shovels for the quantum gold rush”.

***

This article has been adapted from "Lasers to change the world", which originally appeared in the print edition of Ingenia 81 (December 2019).

Contributors

Michael Kenward OBE

Author

Dr Graeme Malcolm OBE FREng FRSE is CEO and Co-Founder of M Squared, a multi-award-winning photonics and quantum technology company. He is a Fellow of the Royal Academy of Engineering, The Royal Society Edinburgh, and the Institute of Physics and his achievements include an OBE for his services to Science and Innovation, the Swan Medal from the Institute of Physics, and Entrepreneur of the Year at the Amazon Growing Business Awards.

Keep up-to-date with Ingenia for free

SubscribeRelated content

Electricals & electronics

Accelerometers

Used in earthquake measurements, laptops, planes and even in stargazing apps, today’s accelerometers are much smaller than when they were first developed in 1927. Find out how they detect movement and vibration.

How to maximise loudspeaker quality

Ingenia asked Dr Jack Oclee-Brown, Head of Acoustics at KEF Audio, to outline the considerations that audio engineers need to make when developing high-quality speakers.

Cable fault locator

The winner of the Institute of Engineering and Technology’s 2014 Innovation Award was EA Technology’s CableSnifferTM, which uses a probe and chemical sensing technology to identify faults, saving energy companies millions of pounds each year.

High speed evolution

In December 2010, Eurostar International Ltd awarded a contract for 10 new high speed trains to Siemens. The company has used a system developed over decades to maximise the performance and passenger-carrying ability of its 320km/h trains.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95