Q&A: Lucy Harden

Lucy representing BAE Systems at the 2016 Farnborough International Airshow, where she demonstrated

the head-up display technology

Why did you first become interested in engineering?

I was very lucky to have some amazing teachers at school who encouraged me to stick with STEM subjects until my A levels, but I wasn’t really sure where they could take me in a career. When I was younger, engineering was the last career I thought I’d get into. I have always been very creative and I wanted to go to drama school to act or be involved in costume design or lighting. Looking back now, building things with LEGO and my love of textile design, combined with the skills I had in maths and science, were the foundation of a career as a mechanical engineer. I always loved watching programmes such as Scrapheap Challenge and Brainiac, which showed me how science can be applied to real life.

How did you get to where you are now?

I ended up taking quite a large selection of A levels at school, purely because I was still unsure of what career to choose. The turning point was being advised by a teacher to take part in the Engineering Taster Week at BAE Systems, a week-long programme where I learned about engineering and fell in love with it. After graduating, I joined its Graduate Development Framework scheme where I was able to work on a variety of projects and product lines.

What has been your biggest achievement to date?

I have been lucky in my career as I have been given so many opportunities to succeed. I think my biggest achievement to date was winning BAE Systems’ ‘Technical Graduate of the Year’ award during my first year on the scheme. I am also incredibly proud of the work we did with UK Sport, where we won an internal Chairman’s Award. I worked on a large range of projects, including one with the Great Britain cycling team’s BMX squad. That project involved using BAE Systems’ cutting-edge optical sensor technology, which was originally developed for unmanned-aircraft. The sensors interact with miniature LEDs on the BMX bikes to track the trajectory of the riders while on the ground and, critically, in the air. This information is then relayed to a specially designed app, giving riders and coaches a real-time read-out of performance, so that they can identify where they can make critical marginal gains. I watched the Rio Olympics with a huge sense of pride last year knowing that I had worked to provide engineering solutions to some of the sport’s biggest challenges.

I watched the Rio Olympics with a huge sense of pride last year knowing that I had worked to provide engineering solutions to some of the sport’s biggest challenges

What is your favourite thing about being an engineer?

One of my favourite things about being an engineer is seeing a rough concept design on a piece of paper turn into something that is physically in your hands and then on an aircraft, flying. I have had the opportunity to meet the end-users of some of our products; it is always amazing to hear how I personally have helped to solve a problem for a customer. I also really enjoy going to schools as an education ambassador where I teach children how science and maths relate to their lives, and how important it is that they stick with those subjects in school. Some of them have come back to complete work experience at BAE Systems, which is really motivating.

What does a typical day at work involve for you?

I generally start my day by assessing the week’s schedule and ensuring that the team is on track against progress milestones and budget. My morning will typically consist of project team update meetings, where we run through each engineering discipline’s tasks and discuss any challenges or opportunities that have arisen. I will then spend the rest of my day working through the aspects of the overall design scheduled for that week, using CAD to turn my ideas into reality. I also have to analyse my design, which may include performing a tolerance analysis to make sure everything interfaces correctly.

Quick-fire facts

Age:

25

Qualifications:

MEng Mechanical Engineering (Hons)

Biggest inspiration:

Richard Branson

Most-used technology:

probably my iPhone

Three words that describe you:

driven, outgoing and enthusiastic

Are there any cutting-edge technologies that you work with?

While on the graduate scheme, I had the opportunity to work on a product called Striker II, a helmet-mounted display system for fighter pilots. This is a digital helmet that allows pilots to fly with their ‘heads up and eyes out’ by projecting flight critical information directly onto the helmet’s visor. This means that while the pilot is conducting fast manoeuvres or evading threats, they do not need to look down at displays in the cockpit to get the information they require. One of the most interesting things for me, from a mechanical engineering perspective, was ensuring that the design was not only cutting edge, but that it provided pilots with the high level of capability and protection that they need to return home safely.

What would be your advice to young people looking to pursue a career in engineering?

Keep going with your STEM subjects! I would also recommend work experience within an engineering company to find out what a typical day looks like for an engineer. There are various engineering companies in the UK that cover a wide range of sectors; I’m sure there will be something of interest for everyone who is considering a career in the industry. I would also recommend becoming a young member of your relevant professional institution, which can provide advice and information on what is going on in the industry. It is also a great way of networking and can sometimes lead to finding a mentor to assist with your career development.

What's next for you?

Within work, achieving our main mechanical design milestones for the product I am currently working on. My next main personal goal is to try and gain professional registration as a chartered engineer with the Institution of Mechanical Engineers, and become a mentor for young engineers to assist with their early career development.

***

This article has been adapted from "Q&A: Lucy Harden", which originally appeared in the print edition of Ingenia 72 (September 2017)

Keep up-to-date with Ingenia for free

SubscribeRelated content

Aerospace

ALMA – the high altitude observatory

The Atacama Large Millimetre/submillimetre Array (ALMA) is the largest and most expensive ground-based telescope built, revolutionising our understanding of stars and planetary systems. Building it in the Atacama Desert in Chile required the ingenuity of hundreds of engineers.

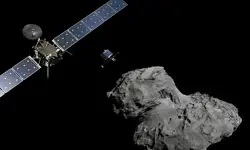

Communicating with outer space

The Royal Academy of Engineering awarded a team at BAE Systems the Major Project Award in June 2016 for their development of a powerful satellite modem system, pivotal in enabling the precise control of the pioneering Rosetta spacecraft and the first-ever soft landing of a spacecraft on a comet.

An aircraft like no other

The Airlander made headlines when it embarked on its first test flight in August 2016 as the world’s largest aircraft. Chris Daniels at Hybrid Air Vehicles Limited, and David Burns, Airlander’s Chief Test Pilot, talk about the engineering that helped it reach this stage and plans for the craft’s future.

Ready to break records

In October 2017, almost a decade of engineering development finally came to fruition when the Bloodhound Supersonic Car embarked upon its first tests at Newquay Airport. Mark Chapman, Bloodhound’s Engineering Director, spoke about how it will attempt to break the world land speed record in South Africa.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95