- Environment & sustainability

- Opinion

- Issue 89

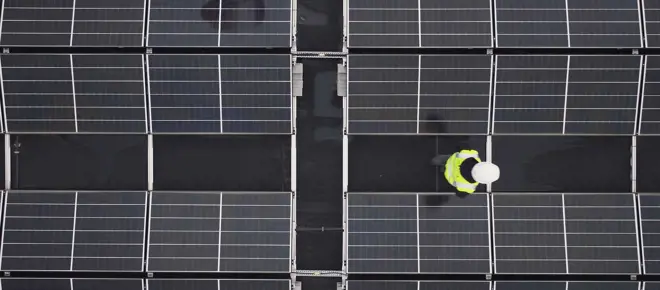

A system is needed to deliver on COP26

Professor Sir Jim McDonald FREng FRSE, President of the Royal Academy of Engineering, reflects on his experience at COP26, hosted in his hometown of Glasgow, and outlines how engineers stand ready to deliver on the commitments made.

- Issue 89

Fuel for a net zero future

Petroleum is seen as one of the greatest evils of global climate change but imagine if we could gain all its benefits without contributing to global warming. Paddy Lowe FREng and Professor Nilay Shah OBE FREng, Co-Founders of Zero Petroleum, write about petrosynthesis – chemical engineering that is being used to create fuels that aim to help achieve net zero.

Quick read

- Chemical

- Health & medical

- How does that work?

- Issue 89

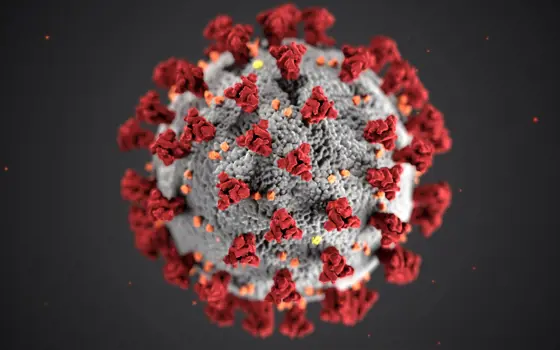

Wastewater epidemiology

Sampling and testing of wastewater is helping governments across the world to track COVID-19 infections on a large scale.

Quick read

- How I got here

- Issue 89

Q&A: Hassan and Hussain Moftah

Hassan and Hussain both had similar interests growing up, which found them following the same career path. They share knowledge, have access to each other’s networks, learn from each other’s mistakes, and are hoping to create a tech start-up together in the future.

Quick read

- Design & manufacturing

- Mechanical

- Innovation Watch

- Issue 89

Machining titanium components

Titanium has a high tensile strength and is light in weight but notoriously difficult to work with. Ed Mason has developed a way to machine the metal and has built a reputation for producing high-end custom-made parts for titanium bicycles.

- Sports & leisure

- Issue 89

Creating pitch perfect sports grounds

When it comes to management of turf in sports grounds, expertise generated in the UK is in demand. The UK grounds-management sector is valued at over £1 billion and has been driven by the large levels of employer and volunteering activity combined with engineering innovation.

- Chemical

- Profiles

- Issue 89

The ethics of engineering net zero

Professor Raffaella Ocone OBE FREng FRSE's career journey encompasses biofuels, carbon capture, and even landslides and volcanoes. She's now pioneering teaching ethics to engineering students.

- Civil & structural

- Issue 89

The sound before the slide

Detecting the early warning signs of a landslip by listening for sounds generated within a body of earth at risk of such movement might seem an unlikely proposition, but engineers at Loughborough University have developed an instrument to do just this.