Creating pitch perfect sports grounds

Did you know?

🐎 UK pitch experts, pitch height requirements and the original mowers

- At 2021’s European Championships, football stadiums across different countries hosted games with allocated UEFA ‘pitch experts’ advising and working with the local groundskeeper on each pitch. All bar two experts (from Ireland) were from the UK

- All sports have different height requirements for grass that increase ball speeds, cushion falling bodies when tackled in rugby or lessen the impact on speeding horses’ legs on racecourses

- Mowers were first operated by humans or pulled by horses, then steam-powered, then petrol engines were used and now the electric version is set to take over

The UK has a long track record of having invented – or claiming to have originated – many outdoor grass-based sports such as football, rugby, tennis, golf, croquet, and lawn bowls. To maintain all these outdoor sports turf surfaces, venues have traditionally employed individuals to look after the pitch, track, or course. These groundskeepers or greenkeepers have learned about the quirks and dynamics of their patch of turf.

When the English Premier League was established in 1992, it triggered an upskilling of these turf-keepers. With extra millions of pounds being poured into the game and the need to attract the best international football talent to the country, the pitches needed to improve. A muddy pitch is a great leveller and doesn’t allow skills and ability to shine. Television needed an attractive and guaranteed performance, as a postponed match meant loss of sponsors’ revenue. It became a requirement for groundskeepers to learn about plant science and new technology was needed to create a reliable and attractive playing surface.

The past and future design of mowers

For hundreds of years, if there was an expanse of grass to be neatly cut, scythes would be used.

Then, in 1830, Edwin Budding, an engineer and inventor, patented the cylinder mower, which produced a clean cut rather than a tearing of the grass. The spiral blades on the machine’s cylinder rotated on a horizontal axis working against a stationary blade that lay flat, just above the ground. That same cutting mechanism principle is still used today by millions of amateur and professional mowers.

Then, in 1830, Edwin Budding, an engineer and inventor, patented the cylinder mower, which produced a clean cut rather than a tearing of the grass. The spiral blades on the machine’s cylinder rotated on a horizontal axis working against a stationary blade that lay flat, just above the ground. That same cutting mechanism principle is still used today by millions of amateur and professional mowers.

In March 2021, the British Engineering Excellence Awards’ New Product of the Year (Mechanical) was given to the C34 Evolution electric lawnmower. Developed by Allett Mowers, these are already being used by Manchester United’s groundskeepers to cut the grass at Old Trafford [see Mechanical product of the year].

Left: Edwin Budding patented the cylinder lawnmower of 1830. This model is from 1888 © Wikipedia. Right: A cylinder mower’s sharpened blade cuts across a fixed blade like scissors through paper © Allett Mowers

The future for mowers is definitely electric, both at the domestic and professional level. Austin Jarrett, Managing Director at Allett Mowers, says: “Electric mowers already represent 50% of our homeowner sales. Now that we have cracked the battery capacity and work rates for the professional sports market, we think that our customers will choose to buy only electric mowers by 2025 and then we’ll stop producing petrol-powered mowers.”

Electric machines means that there are no particulate emissions at point of use and no need for storing large amounts of petrol on the premises. There is no pull cord to start the mower and less hand arm vibration for the operator, thereby reducing the risk of white finger – a condition caused by long-term exposure to vibrating machinery.

Professional football pitch mowers get a lot of use. During the summer months a pitch will get cut once or twice a day, seven days a week to a height of between 22 and 25 millimetres. During the winter months, groundskeepers tend to mow less than three times a week, let the grass grow to 24 to 30 millimetres, and then double cut the day before game day and once on the day itself.

Now that we have cracked the battery capacity and work rates for the professional sports market, we think that our customers will choose to buy only electric mowers by 2025 and then we’ll stop producing petrol-powered mowers

Top models have a three-section rear roller that have double-differential steering (differential transmits equal torques to the roller outer sections allowing different speeds), which makes it easy to turn at the end of a run at a pitch’s edge. The centre section always drives and then the left and right independent sections enable one section to spin quicker than the other. It also operates at a different speed from the cutter, which helps when turning corners.

These mowers not only cut grass but help the groundskeeper with a host of other pitch maintaining tasks. They have changeable ‘cartridges’ that sit just behind and above the front roller that perform different tasks. There is a six-, eight- or ten-bladed cylinder for cutting, a spiked one for aerating, and others will scarify, rake, aerate, and brush. There is also the ability to raise, in 2- or 3-millimetre increments, the cutting blade’s height.

The Allett C34 Evolution weighs 160 kg with cartridge loaded and is balanced so that a downward force equal to only 7.5% of its weight applied to the wide handle bar is needed to pull up the front end © Laura Malkin, Allett Mowers

Mechanical product of the year

The electric Allett C34 Evolution walk-behind mower has three patents pending and is as powerful as its petrol predecessor. The mower is powered by an 82 volt battery system consisting of four 6 Ah Lithium-ion batteries that can cut 6,000 m² of grass per charge. The batteries are interchangeable, so can fit other tools such as brush cutters, leaf blowers and chain saws, and take 90 minutes to recharge.

One of the patents pending is for the control-drive system that allows the speed to be lowered when turning. As there’s usually quite a lot of juggling at the end of run – such as pulling the mower back and lining up the next drive, which can both damage the turf as well as require upper body strength – reducing the mower speed temporarily helps.

The eight hardened-boron-alloyed blade cylinder makes 95 to 190 cuts per metre and can be sharpened by a novel ‘back-lapping’ feature. John Gittins, Allett’s Engineering Manager, explains: “Rather than buy a separate machine to attach to your mower and sharpen the blades, you can back-lap the C34 E’s cutting cylinder. Because it’s electric and can be slowed, you can reverse its direction by using a hand-held pendant that makes the operation much safer, as you dictate when it stops. The groundskeeper will then use a cutting paste such as grease with grit in it to sharpen the blades.”

Methods of achieving a year-round playable surface

It’s only a few decades ago that by the time November came along, football and rugby pitches would resemble a quagmire, with the players covered in mud by the final whistle. In football, there has been a revolution in grounds management and a greater holistic understanding of what makes a near-perfect pitch to play on.

Dr Christian Spring is the Research Operations Manage at the Sports Turf Research Institute (STRI). The STRI provides research and science services to the sports industry all around the world, as well as design and consultancy input. Dr Spring says: “In many ways, a modern football stadium is like an amphitheatre: it has to house a lot of people and give them a good view of the action. Its sides will probably be tall, with a lot having overhanging or sliding roofs to keep the rain off their match-day customers. That means that the available light for growing grass is limited especially in the winter when the sun is lower, which means that additional technological support is needed to heat the soil and provide light for the grass plants.”

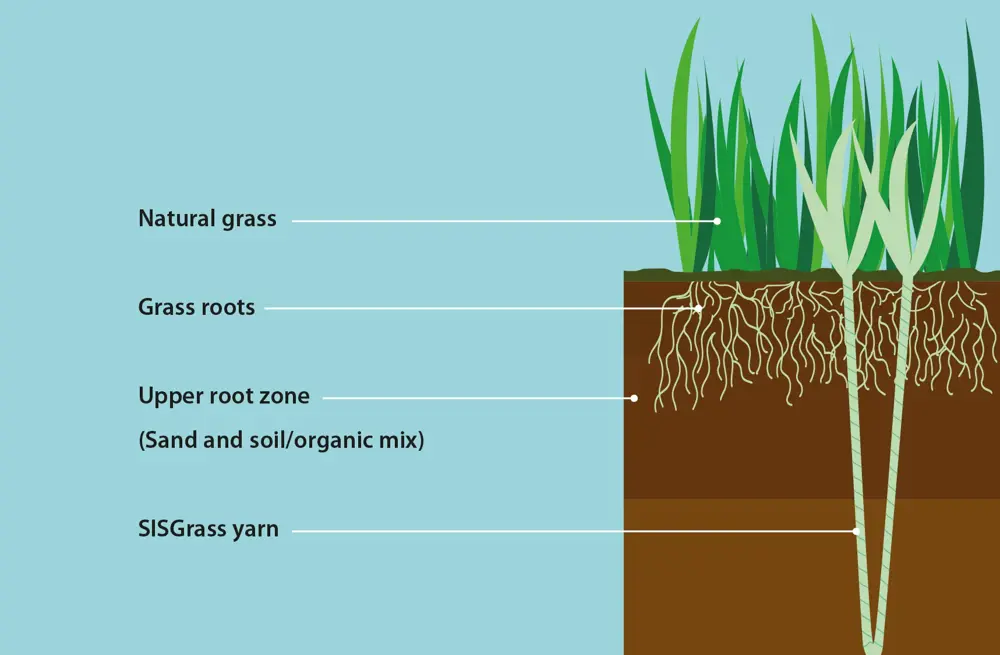

SISGrass is an example of a stitched hybrid grass system

There is now an established tick list for achieving a year-round, 60-match playable surface. From the bottom up, there should be geotextile membrane, above which lie drainage pipes set in a gravel drainage layer. Undersoil heating, obligatory in all Premier League grounds, will sit in a sand surround. Above that will be the grass roots, an upper root zone topped by the grass plants themselves.

A relatively recent addition to this upper layer has been artificial grass. It may not be immediately obvious but nearly every club in the top two divisions of the English league has got some kind of hybrid pitch. This will consist of natural grass – usually perennial rye grass – supported by either polypropylene or polyethylene fibres.

There are two main methods used for laying the artificial grass across cricket, golf, rugby, and football pitches. In 2020, Wembley Stadium had the stitching method used to apply 75,000 kilometres of artificial grass 200 millimetres deep into the layers of sand beneath the pitch. Above the pitch, the artificial grass sits a few millimetres below the height of the natural grass. This reinforcement of the rootzone provides shear stability, enabling players to generate large horizontal forces – like turning and sprinting – without taking chunks out of the turf. Wembley’s grass-surface now consists of 97% organic and 3% artificial grass.

This reinforcement of the rootzone provides shear stability, enabling players to generate large horizontal forces – like turning and sprinting – without taking chunks out of the turf

The other method is termed a carpet system whereby an artificial grass carpet is placed on top of natural grass. It is a quicker method and has a slightly higher percentage artificial content ratio.

Above ground, there are a few more items used to ensure that grass can keep growing within a stadium all year round. Grass needs sunlight, water and nutrients to thrive. Water sprinklers are standard kit nowadays to cover dry periods and LED lighting is being used to help shaded areas of pitch. These are used to replicate the red and blue wavelengths needed for photosynthesis and to ensure grass growth, recovery and the plant’s resistance to disease. Photosynthetic LED use is now expanding into other sports such as golf and cricket.

Assessing how a sports surface is going to play

To apply standards, as well as to research what works best for grass and turf, there is a need to quantify the various types of treatment and conditions. Among the tools used are ones that have been developed for other applications but found to be useful in assessing how a sports surface is going to play. One of these is the Clegg Impact Hammer, originally made for civil engineering purposes to determine the hardness or shock absorption properties of a surface.

Golf uses a half kilo Clegg hammer but cricket and winter sports use a 2.25 kilogram compaction hammer dropping through a vertical guide tube from a half-metre height. The deceleration rate is determined by the ground’s hardness and the readout registers the hardness values in units of gravity. For cricket, the test is a good indicator of bounce and pace. For football and rugby, there needs to be consideration of both ball bounce and player impact safety.

Amateur sports pitches at all levels have benefited from the knowledge passed on by the Pitch Advisory Service © Shutterstock

A high gravities reading could indicate that a ground has become overly compacted and will need aerating. Too light a reading could indicate the ground is overly soft and wet. Horse racing has its own device called a Going Stick that measures the resistance of ground penetration and the shear – the energy needed to pull the stick back to an angle of 45° thus mimicking the pressure of horses’ hooves hitting the ground. The readings are fed back as the track being: heavy, soft, good or firm going.

A penetrometer is an instrument used at the grassroots level of the game – in both senses of the word. It is used widely by groundskeepers at a local level looking after sport pitches. Pushed into the ground, it too measures a turf’s compactness. The remedy for compact ground in a small area can be a hand-held fork, for a wider area it could be a machine that provides vertical aeration. Grass roots need air spaces in order to grow and if squashed by soil, the grass plant will have difficulty flourishing.

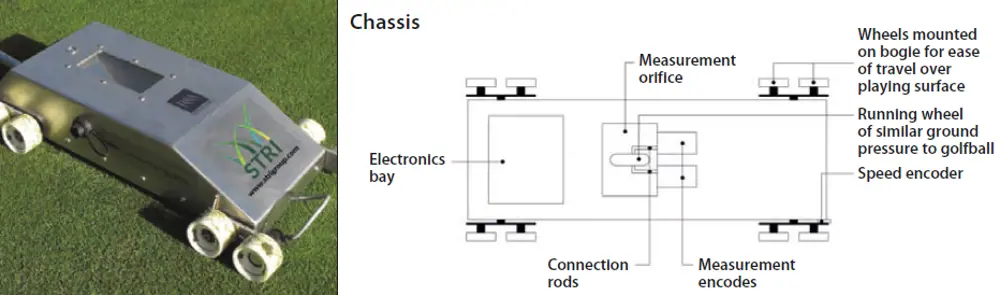

Most sports at an elite level use a sloped instrument that measures how a ball rolls on a surface. The stimpmeter in golf is used by all courses to measure the speed of the greens. It is a small aluminium ramp with a v-groove cut in it that releases the ball when it reaches an angle of 20°. Measuring the average distance with three rolls in two opposing directions will give a rolling length in feet. Usually 10 feet (3 metres) is considered a good green speed. The STRI has developed the Trueness Meter used across hundreds of courses worldwide that looks not just at the speed but the quality of the roll.

Collecting data to inform golf course management

The STRI Trueness Meter assesses the amount of deviation of a rolling golf ball and collects data that can be used to inform golf course management. Consultants use the instrument to measure vertical deviation (smoothness) and lateral deviation (trueness) of a replica golf ball. The lower the numbers, the more smooth and true the surface. Smoothness readings of 16 to 18 mm/m and 6 to 8 mm/m would be worthy of a major golf tournament course. Above 23 mm/m and 10 mm/m would indicate that a golfer’s shot would have little chance of following the line that they had played. Further analysis of the green would enable advisers to suggest remedies including verti-cutting, rolling, getting rid of thatch, and other measures that would enable the green speed to be kept, without excessive deviation of the ball.

The STRI Trueness Meter used to assess the amount of deviation of a rolling golf ball © STRI

Finishing touch to make the pitch sparkle

There is one inexpensive grass tip that is universally shared by groundskeepers across all sports. When all the hard work has been done with the drainage, the scouring, the hoovering of the pitch with a rotary mower before the game there is one finishing touch that can make the pitch sparkle that little bit more. If it needs it, a groundskeeper will spray liquid iron onto the turf a day and a half before a game. Iron sulphate is a turf tonic that strengthens the grass blade and as Jason Booth says: “I wouldn’t call it cheating, spraying paint on the grass was cheating. I’d say it greens up the green, it enhances the aesthetic."

***

This article has been adapted from "Pitch perfect engineering", which originally appeared in the print edition of Ingenia 89 (December 2021).

Contributors

Dominic Joyeux

Author

Austin Jarrett

Managing Director, Allett Mowers and SSC Laser

John Gittins

Engineering and Quality Manager, Allett Mowers

Steve Robinson

Sales Manager, Thorncliffe groundcare (previously Business Development Manager, Allet Mowers)

Jason Booth

Chief Operating Officer, GMA

Dr Christian Spring

Principal Research Scientist, Sports Turf Research Institute

Keep up-to-date with Ingenia for free

SubscribeRelated content

Sports & leisure

How technology enhances the Wimbledon tennis experience

The All England Lawn Tennis and Croquet Club (AELTC) and IBM worked closely together since 1990 to harness innovative technology to transform The Championships into one of the most popular and technically advanced events on the international sports calendar.

Noise-cancelling headphones

Used by plane and train passengers wanting to listen to radio, music or film without hearing background noises, active noise-cancelling (ANC) headphones are able to prevent outside noise from leaking through to the inside of headphones.

How to create the perfect wave

From small waves lapping at your feet and swells suitable for surfing to storm waves for testing structures and even tsunamis, waves of any shape and any size can now be engineered. What are the techniques and conditions needed to model waves and what makes some more powerful than others?

Going for gold

The success of Great Britain’s cycling team at the 2016 Rio Summer Olympic Games was celebrated, but what about the closely guarded technology that contributed to their success? The engineering approaches taken to shave as much time as possible off the clock are spoken about by Professor Tony Purnell.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95