Failed development to efficient office skyscraper

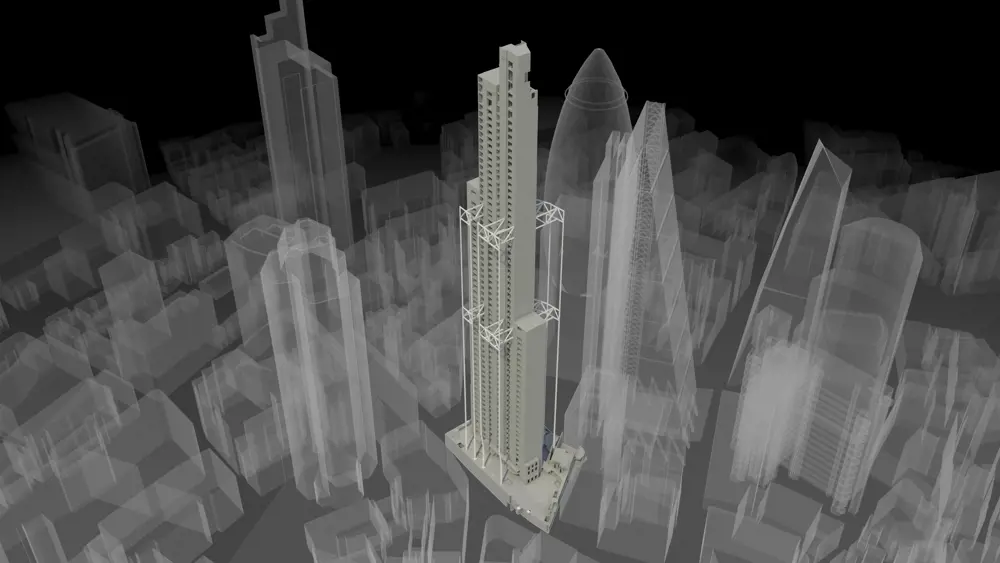

Modern high-rise work spaces in the City of London have led to a succession of instantly recognisable iconic structures with quirky nicknames – ‘The Gherkin’, ‘The Walkie-Talkie’ and ‘The Cheesegrater’. The tallest and most eye-catching of all was set to be ‘The Pinnacle’, a twisting, tapering tower, provisionally nicknamed The Helter Skelter. However, following the 2008 property crash, the investors pulled out and the project stopped. By then London’s deepest piles had been sunk, most of the three-storey basement had been built and the first seven stories of the building’s concrete core had been erected above. Efforts to revive the scheme came and went, and the desolate, abandoned concrete soon acquired a new nickname: ‘The Stump’.

Although widely admired as an architectural masterpiece, The Pinnacle had severe drawbacks. It was inefficient and expensive to build: its tapering, spiralling shape allowed little opportunity for repetition in construction with its highly complex engineering and irregular floor spaces. Also, post-2008 developers wanted efficient buildings, attractive to both businesses and their employees, which would help draw activity back into the City. A very different building was required, one that used the size and shape of the plot more efficiently, and was affordable to build.

The challenge was taken up by Lipton Rogers Developments (LRD), with its architect PLP, engineers WSP and contractor (as for The Pinnacle) Multiplex. LRD had jointly run an exercise with the City on how to construct high-rise buildings quicker and cheaper, and this was a chance to put the exercise into practice. The challenge was to create a building the same height as The Pinnacle, but with a third more lettable space, no more weight and at less cost.

Air traffic control

✈️ Structural engineers rarely get involved with air traffic control, but a very tall building under busy flight paths is an exception.

The flight path to London City Airport is directly over the City of London, with planes normally at more than 600 metres but with a safety zone down to 305 metres to allow, for example, for failure of a plane’s engines. The building was designed to fit within this limit, but the designers had assumed that cranes would be allowed to rise higher during construction – as was the case with The Shard across the river to the south (‘Building The Shard’, Ingenia 52). When planning permission came through with a surprise 309.6 metre limit on crane height, a quick redesign of the top of the building and how it would be assembled was required, with the topmost crane only allowed to operate with its jib horizontally. Eventually through negotiation, the restriction was lifted outside flying hours so that the jib could be raised – between 11pm and 6am Monday to Saturday and all day on Sundays. A ‘hotline’ was installed with City Airport so that the site could check that all flights had stopped before they lifted the jib, and to confirm that the jib was locked down before flights could restart.

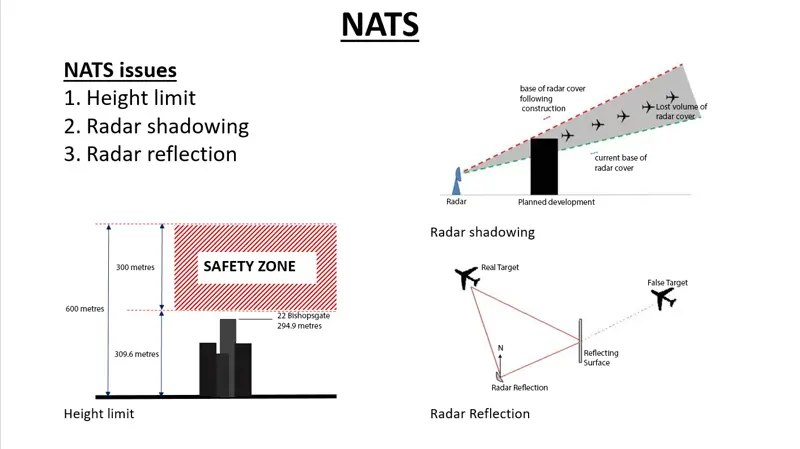

The flight paths in and out of Heathrow are at a much higher level, but the issue here was interference with the radar operated by Britain’s air traffic control service NATS – either shadowing, which would hide some aircraft, or reflection, which would cause aircraft to appear on the radar in the wrong place. An impossibly low height limit was imposed on the building until a solution could be found.

LRD quickly identified that the 112-metre-high 1960s Hyde Park Barracks was directly in line between the NATS radar station at Heathrow and Twentytwo, thereby casting its own shadow. This allowed the height restriction to be raised to the top of the ‘shadow’, at 126 metres, which bought time for a long-term solution. LRD worked with NATS to create software effectively cross-referencing readings from two separate radar stations to eliminate the risks.

Air traffic control issues show the safety zone for London City Airport approaches, which limited building height to 309.6 metres, and the effects of shadowing and reflection on NATS radar © Lipton Rogers Developments

Building foundations

The basic design of the new 62-storey block, provisionally dubbed Twentytwo, is conventional by modern skyscraper standards: a large central concrete core holding the lifts, steel columns and beams around the periphery and concrete floors in between. The difficulty came at the bottom. The columns and core were not in the same place as The Pinnacle’s existing piles. Installing new piles would be expensive and would delay the start of construction by many months.

The core of the old stump had to go, but much of the existing basement and all the old piles could be re-used. This required a series of engineering measures to transfer the huge loads from the core and columns of the new building on to more than 300 existing piles – 25 mega-piles installed for The Pinnacle plus other smaller piles from previous developments - using their bearing capacity to the full without overloading any. In the end, engineers only needed 85 new piles, most to lend support to the larger concrete core, and these were small enough to be sunk with a small piling rig that could fit inside a basement storey.

The difficulty came at the bottom. The columns and core were not in the same place as The Pinnacle’s existing piles. Installing new piles would be expensive and would delay the start of construction by many months

Columns along the west edge of the building slope inwards between levels six and three, with the huge horizontal forces countered by horizontal trusses connecting the columns to the concrete core © WSP

In many places, the transfer of load to the existing piles was achieved by installing massive beams within the basement area – effectively one-metre-thick reinforced concrete walls up to three storeys high. However, along the west side, the huge loads from the peripheral columns had to be brought in to the piles located much nearer to the central core. Engineers could do this by sloping the columns inwards from level six to level three, returning to vertical for the entrance lobby down to ground level, and then sloping again from ground to basement three. Sloping introduced massive horizontal forces that pushed outwards at the top of the sloping column and inwards at the bottom. To resist these, large steel Warren trusses (steel members arranged in a triangular grid) were installed in a horizontal plane just beneath the floor to connect the line of columns with the solid concrete core – a truss at the top of the sloping column to take the tension and another at the bottom to resist compression.

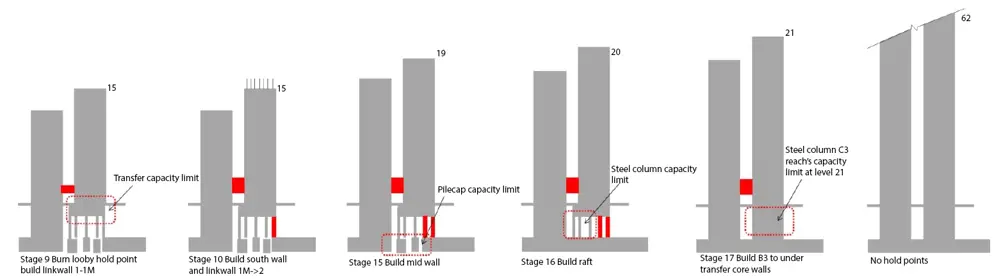

Sequence of ‘top-down-bottom-up’ construction for the south core, showing the additional strengthening measures to allow the core to be increased to level 20 before the foundations below were completed © WSP

Fire safety

🚒 The lifts that convert to ‘vertical tube trains’ in the event of a fire

Twentytwo has all that would be expected in terms of fire safety in a modern tall building, including careful choice of building materials, compartmentalisation to prevent fire spread, a fire-engineered structure to allow at least a four-hour safe period for evacuation, smoke control, four dedicated lifts for firefighters and a conventional ‘down-the-stairs’ evacuation procedure. But, as a first in the UK, the lifts will also convert in a fire to ‘vertical tube trains’ for rapid evacuation.

When the external cladding of the Address Downtown tower in Dubai caught fire in 2015, the remainder of the building’s fire safety strategy worked well enough to prevent serious injuries – apart from one person who suffered a heart attack during the evacuation. Hurrying down some 60 flights of stairs can be exhausting for fit people, and with the UK population getting less fit, using the lifts makes sense. However, this is usually ruled out as too expensive: using lifts in fires requires fire-rated shafts, dual power supply, cars pressurised against smoke ingress and large lift lobbies free of flammable material.

LRD’s ingenious solution has avoided these costs. The building is divided vertically into zones, with fire-hardened floor slabs with a two-hour fire rating separating them at levels 26, 42 and 58, which coincide with the levels served by each of the groups of lifts. Each set of lifts has a motor room just above the fire-hardened slab, itself encased in concrete.

A fire on the lower floors will still require a conventional evacuation, but if a fire is detected at a higher level, lifts will spring into action to evacuate people from floors up to the nearest fire-hardened slab beneath the fire. LRD estimates that the top three floors could be evacuated in just 20 minutes, a third of the time it would take if everyone used the stairs.

For one of the columns near a corner of the building, the truss solution would not work for the tension, so instead the top of the sloping column was anchored in to the core with an array of high-strength steel cables, sheathed and embedded in the concrete floor and then made tense.

Site constraints created other challenges. The old basement included two lorry lifts, which was the main means of access to the lower levels during construction and not easy to relocate, so the structure above had to bridge over it. Engineers designed a ‘mega truss’ to transfer the load from three of the main columns to the pile caps via columns either side of the lift. Elsewhere, basement space was needed for delivery or waste-collection lorries to turn, requiring one column to be removed. A massive 15 metre-long, 3.8 metre-deep, 97-tonne steel ‘mega girder’ was inserted just below the ground floor slab to transfer the load to points where there was sufficient pile capacity.

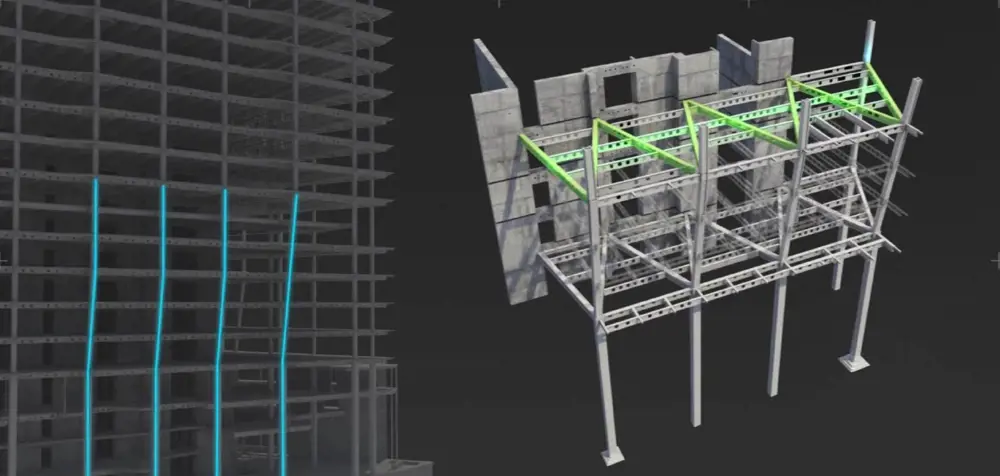

The north side of the new concrete core sits over the adequate foundations of the old core, but the south side required new piles and a new heavy concrete raft to be constructed first. The solution here was to adopt ‘top-down-bottom-up’ construction. A massive grillage of columns and beams was assembled in basements one and two to support up to 15 storeys of core above. This left basement three free for work to continue on the foundations beneath – with everything above supported on just four columns. As construction of the core proceeded faster than the foundations, the contractor asked if the grillage could support another six stories of core: this was achieved with additional strengthening and temporary columns, and by the time the core reached 21 storeys the new foundation was complete and the temporary grillage could be dismantled.

A building with smart technology

Twentytwo will have some of the smartest technology yet seen in a large building, helping to control the building services and provide a higher level of service to tenants and workers.

All office buildings have some form of building management system (BMS) linking and controlling the heating, cooling and electrical systems. The BMS at Twentytwo is large-scale, reflecting the size of the building, but the innovation lies in an overarching smart building platform (SBP), created with automation software provider Iconics, which collects and analyses data from the BMS and other systems in the building. With half a million sensors on the BMS alone, the amount of data is enormous and the opportunities for applying artificial intelligence to analyse and utilise this data are many and varied.

Twentytwo will have some of the smartest technology yet seen in a large building, helping to control the building services and provide a higher level of service to tenants and workers

At a simple level, this helps optimise energy use. The SBP may also, for example, learn over time that failure of a fan on a chiller unit is usually preceded by a characteristic change in vibration of the unit: it can then spot the vibration change, order a new part and generate a work order for replacement before the unit fails. On a larger scale, this could eliminate all unexpected equipment failures, and do away with regular, planned maintenance – improving quality and reducing maintenance costs. Or the system may spot that sales of a particular item in a catering outlet spike when the weather is humid: data from the weather station located at the top of the building can then advise the caterer when to increase stocks of that item.

The system is also linked to the 9,000 blinds installed within the sealed triple glazing of the building’s full-height windows, to limit both heat gain and glare. The blinds are normally fully open, but are lowered automatically depending on the intensity of sunlight, detected from the weather station, as well as by the temperature in the room. An integrated 3D model of surrounding buildings allows the system to adjust blind heights for shadowing and for reflected solar glare.

The control software for the lifts is also linked into the system. For example, if the system is forewarned of many visitors arriving, it can order additional reception staff and ensure that the right lifts are in place on time to take the visitors to their meeting. In case of fire, it can automatically switch the appropriate lifts to evacuation mode.

A facial recognition system – faster and less intrusive than those often found at airports and never before used on this scale – replaces security checks for regular staff, making entry to the building a seamless process. It also provides a live record of who is in the building.

Tenants can be provided with almost any information they ask for. They can set their own heating and cooling controls, but then be informed of their energy consumption with suggestions for improving efficiency. At a more innovative level, data from movement sensors used to control lighting, linked to IT data on time and place of each person’s log-on, can be used to identify parts of their floor that are underused, or reveal how well Team A on one side of their floor is integrating with Team B on the other.

The full scope of the SBP is deliberately undefined. It is designed with flexibility in mind, to accommodate both future demands and future developments: technology is changing fast, but the building is set to be here for a long time

The system will also allow the building’s sustainability credentials – for the building as a whole or just a tenant’s area – to be monitored in real time, not just the one-off measure required by conventional certification systems.

Besides a BREEAM Excellent sustainability credential, Twentytwo was the first big UK building to be registered for the WELL Building Standard, which focuses on how buildings can enhance, rather than compromise, people’s health and wellness. This helped drive the high ceilings and maximum natural light of the design and the provision for cyclists, and rewarded other features such as attractive stairwells that encourage staff to walk rather than use lifts. It also requires features such as air quality to be measured and certified – easy to achieve with output from the SBP.

The full scope of the SBP is deliberately undefined. It is designed with flexibility in mind, to accommodate both future demands and future developments: technology is changing fast, but the building is set to be here for a long time.

Stopping sway and avoiding the ‘windy city’ effect

For wind loading, the design to avoid toppling is straightforward: the real challenges are to limit sway to levels that occupants do not find disturbing, and to avoid the ‘windy city’ effect of creating strong currents of air around the building, particularly near ground level. Engineers carried out extensive modelling and computer simulations, involving Formula 1 expertise in computational fluid dynamics.

The concrete core containing lifts and providing the primary means of stability for the building, showing the two-storey high steel outriggers at levels 25 and 41 and vertical steel ‘belts’ embedded in the facade to limit sway. The core gets smaller nearer the top, as some of the lifts serve only lower floors © WSP

The building itself and its concrete core are roughly rectangular and movement along the long edge was not an issue. To limit sway along the short edge, where the width of the concrete core is only 14 metres and the orientation causes greater wind loads, double-storey outrigger steel trusses were installed at levels 25 and 41 between the core walls and the periphery, where they were connected to the columns.

Concrete shrinkage, compression of concrete and steel under load, and settlement of piles all lead to significant movement in such a tall, heavy building. Movement differs significantly between the concrete core and the peripheral steel columns: 60 millimetres in total for the concrete and 200 millimetres for columns where the stresses are greater. This movement was anticipated and dimensions adjusted accordingly, but it meant that bolts connecting the outriggers to the structure could not be tightened until after the building had been ‘topped out’ in May 2019.

Meanwhile near ground level, the complex array of baffles developed through modelling and computer simulation to create a wind-free environment have been neatly integrated with artwork, so that they appear creative rather than merely functional. LRD’s vision for 22 Bishopsgate was to create a community rather than a collection of standalone tenancies – a ‘vertical village’ of some 13,000 people – and most of the design features of the building stem from this vision: higher ceilings and full-height glazing for natural light; hassle-free entry and lifts; common amenities, such as London’s largest bicycle park in the basement, plus a communal food hall, an external terrace, a business club, a wellness centre and gym, a relaxation zone and an innovation hub, to help improve work/life balance; flexibility for tenants to create their own space and to allow for future changes of use; and a state-of-the-art technological backbone that is a first for a new building in the UK [see A Smart building].

***

This article has been adapted from "A square peg in a round hole", which originally appeared in the print edition of Ingenia 80 (September 2019).

Contributors

Hugh Ferguson

Author

Peter Rogers CBE FREng is Co-Founder of Lipton Rogers Developments. He is an engineer and property developer specialising in delivering complex building projects, working with government and industry to improve environmental and working practices in construction He was awarded a CBE for services to construction in 2007, is a Fellow of the Royal Academy of Engineering and the Royal Society of Arts, and an Honorary Fellow of the Royal Institute of British Architects.

Keep up-to-date with Ingenia for free

SubscribeRelated content

Civil & structural

Building the Shard

The Shard is one of London's most iconic buildings. The tallest in Western Europe, it was designed by Italian architect Renzo Piano and dominates the city’s skyline. Ingenia spoke to John Parker, project director for structural engineers WSP, who outlined the engineering decisions made in building the enormous steel and glass structure.

FlexiArch

Arch bridges are strong, durable and require little maintenance. However, very few had been built since the early 1900s until the FlexiArch was developed and launched in 2007. Now, there has been a minor renaissance for this ancient form of construction.

Creating user-friendly buildings

For Michelle McDowell, a former Business Woman of the Year, a passion for joined-up design thinking and building information modelling with a user-friendly approach has enabled her to pioneer revolutionary changes in her field.

Troja Bridge

In November 2014, one of the world’s largest network arch bridges was officially opened in Prague. The UK may soon have its first network arch bridge if the go-ahead is given for a new rail project in Manchester.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95