Non-alcoholic beer and wine

More and more people are drinking less alcohol. In 2022, half of all adults in the UK bought a no- or low-alcohol product and 85% of UK pubs sell at least one low- or no-alcohol beer. Much of this increase in sales can be attributed to brewers launching products that still taste ‘authentic’, made using high-quality ingredients and more advanced methods.

Two main methods are currently used for producing alcohol-free drinks: vacuum distillation and reverse osmosis. Generally, manufacturers will make the beverage, such as beer or wine, as usual and then remove the alcohol content.

Vacuum distillation takes place at reduced pressure, which decreases ethanol’s boiling point. Alcohol boils at a lower temperature than water, so reducing the temperature means that the ethanol evaporates from the liquid while preserving its flavour. This technique is particularly popular with winemakers. It has two stages: the first takes place at 30°C and strips volatile compounds from the liquid. The second stage at a higher temperature removes the alcohol.

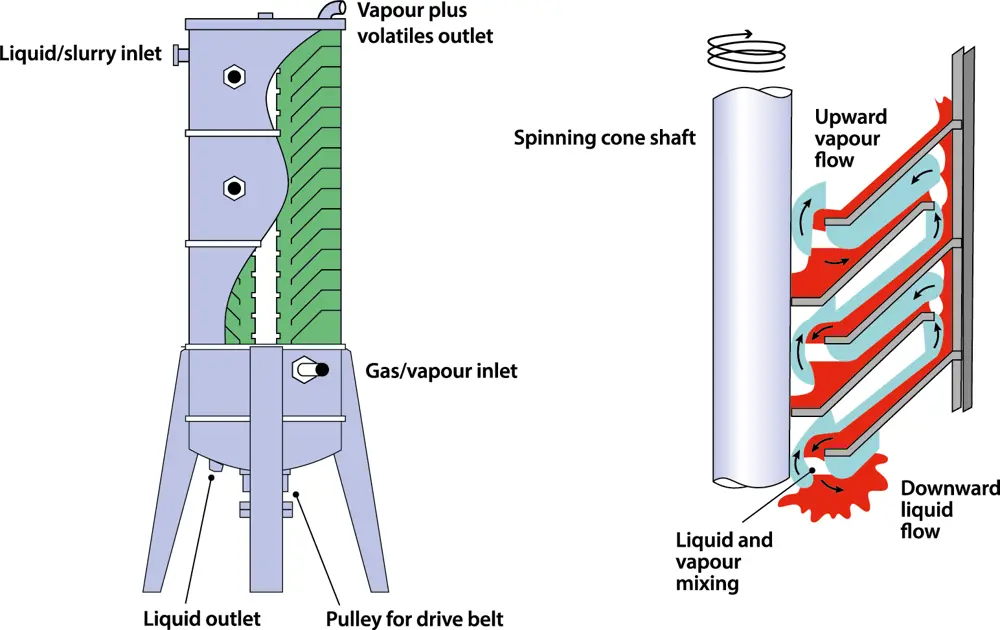

The process takes place inside a stainless-steel column. A series of alternating spinning and stationary cones are attached to its inner wall and on a central rotating shaft inside. The liquid is fed into the top of the column under vacuum while steam enters from below. The spinning cones generate centrifugal force that creates a thin liquid film that moves over the cones, and the volatile compounds evaporate into the steam at low temperatures. The liquid is again passed through the column at a higher temperature to remove the alcohol through evaporation.

Vacuum distillation takes place inside a stainless-steel column. Within this, the liquid is passed through a series of spinning cones to form a thin liquid from which the alcohol evaporates © diagram adapted from Flavourtech.com

Other manufacturers use membranes that allow water and alcohol to flow through them but not flavour compounds, which are larger molecules. This process, called reverse osmosis, is more commonly used to brew beer. To increase the volume once the alcohol has been removed, brewers will add fresh water to the flavoured liquid or distil the water that has been removed and blend it back into the liquid once the ethanol has boiled off.

Brewers also use other methods, such as not adding yeast or using special strains of yeast so that the mixture does not ferment. Another approach is to ferment at low temperatures to produce low amounts of ethanol. However, many of these processes result in dull or little flavour.

As demand grows and well-known drinks manufacturers and premium brands move into the low- or no-alcohol arena, producers are searching for the latest techniques and technologies. Guinness has almost tripled production of its zero-alcohol brand at its Dublin brewery and brewers across the UK and beyond are experimenting with innovative brewing processes. Since January 2023, wine producers across the European Union have been able to produce and market de-alcoholised wine with an alcohol content below the previous minimum threshold of 8.5% ABV. In this way they can meet the demand for non-alcoholic wine and encourage winemakers to innovate further.

Keep up-to-date with Ingenia for free

SubscribeRelated content

Chemical

Q&A: Olivia Sweeney

Olivia Sweeney sources aroma chemicals to create fragrances at cosmetics company Lush. She is working on finding new, more sustainable sources of fragrance ingredients, with an interest in the research and development of chemical production from waste streams.

Biofuels’ journey to the mainstream

Liquid biofuels today make up about 8% of road and non-road fuel supplies in the UK. The government plans to reach nearly 10% by 2020 in order to reduce CO₂ emissions. It has also laid out targets to incentivise innovation and the production of ‘development fuels’.

Compostable plastics

Compostable plastics can be turned – alongside food and other organic waste – into compost. But how environmentally friendly are they really?

Q&A: Michelle Watiki

From placements at Xerox and Rolls Royce, to becoming a board member for the Association for Black and Ethnic Minority Engineers, chemical engineering graduate Michelle Watiki hopes to apply her knowledge to sustainability and net zero, as well as helping future engineering students.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95