Tapping the power of the tides in the UK

COAST’s ocean basin can generate waves and currents to enable testing of new energy technologies © COAST, University of Plymouth

As an island nation with an estimated 20,000 kilometres of coastline, the UK is well placed to harness energy from its oceans. Yet despite the first patent for wave power being filed in France back in 1799, it was the mid-1970s before the British government began seriously exploring the potential for coastal and offshore energy generation. By 1982, with North Sea oil abundant, the government abruptly terminated its wave energy programme, and it would be many years before this fledgling industry regained the momentum it had lost.

While wave and tidal energy is a potentially attractive approach, it has faced significant engineering and cost challenges when compared to offshore wind. Slow adoption of wave and tidal energy is partly caused by the challenging nature of the oceans. They are incredibly hostile environments for any human-made device to survive in, let alone operate efficiently. Wave and tidal energy hardware is subjected to abrasion, corrosion, bio-fouling, and electrolytic reactions, while being battered by hurricane-force winds and the sheer power of tonnes of moving sea water. There are also different challenges depending on whether wave or tidal energy is being harnessed. The former relies on wind blowing over water, and wave energy devices have to withstand sudden gusts of up to 100 kilometres an hour. Tidal power exploits changes in sea level and tidal currents, making it far more predictable, but the UK’s attainable tidal resource of 20 to 30 terawatt-hours per year is only around half the level offered by wave energy.

Because of the extreme weather conditions found offshore, testing new hardware or energy production processes rarely takes place in the depths of the ocean. Instead, prototypes and scale models are tested in relatively controlled environments. These increasingly sophisticated facilities can replicate the environmental challenges of the open ocean, while measuring and recording activity using advanced (and often delicate) monitoring equipment.

Two separate testing centres at opposite ends of the country are enabling partner organisations to develop innovative and robust solutions to the many challenges of offshore energy generation. Their work demonstrates how ingenious engineering can be used to harness some of the planet’s most untameable natural resources.

The COAST hydrodynamic testing facility

At the University of Plymouth, the Coastal, Ocean and Sediment Transport laboratory has been performing hydrodynamics testing since 2012. Known by its acronym COAST, the testing facility has already been used in 60 commercial projects as an alternative to expensive and time-consuming sea trials. Its centrepiece is a huge ocean basin that measures 35 metres by 15.5 metres, with a moving floor supporting a water depth of up to three metres. Below the surface, 24 two-metre hinge depth paddles, powered by electric motors and supported by pressurised air cylinders, counterbalance the water pressure. Each paddle is regulated by software capable of replicating mathematical models of recorded sea activity, generating multidirectional waves over a metre in height in tandem with recirculating currents. A prototype wind system has also recently been installed, to further improve the basin’s flexibility as a test bed by replicating storms and freak weather events.

These realistic and repeatable sea states are ideal for manufacturers and energy providers to test and refine their hardware, as COAST’s lead technician Alastair Reynolds explains: “Wave motion changes far more than other sources of renewable energy. Wind motion tends to be fairly consistent over a period of hours, whereas waves are constantly changing in their height, amplitude and power. A device capable of harnessing this energy must constantly adapt to changing conditions. Because of these issues, no design of wave energy converter has been accepted as the industry standard yet.”

Wave motion changes far more than other sources of renewable energy. Wind motion tends to be fairly consistent over a period of hours, whereas waves are constantly changing in their height, amplitude and power

The different types of wave energy converters

To date, three main types of wave energy converters have been developed:

- Oscillating water columns use trapped air pockets in a water column to drive turbines for electricity generation.

- Oscillating body converters convert wave motions into device oscillations to generate electricity.

- Overtopping converters deploy reservoirs to generate a head flow that subsequently drives turbines for electricity generation.

Each has different merits and optimal use scenarios – fixed oscillating water columns and overtopping devices work well along shorelines, whereas floating wave energy converters are generally required offshore. However, all three conversion methods face the same challenges, according to Professor Deborah Greaves OBE at COAST: “It is important for wave energy converters to survive extreme waves during hurricanes and storms. Most of the reliability and survivability studies undertaken to date have been based on computer modelling or laboratory scale tests, and long-term at-sea field experience is needed now to secure confidence in the sector. Excellent progress has been made in numerical modelling for wave energy convertor concepts and it is important to build on this to provide high precision analyses, especially under extreme wave conditions.”

It is important for wave energy converters to survive extreme waves during hurricanes and storms

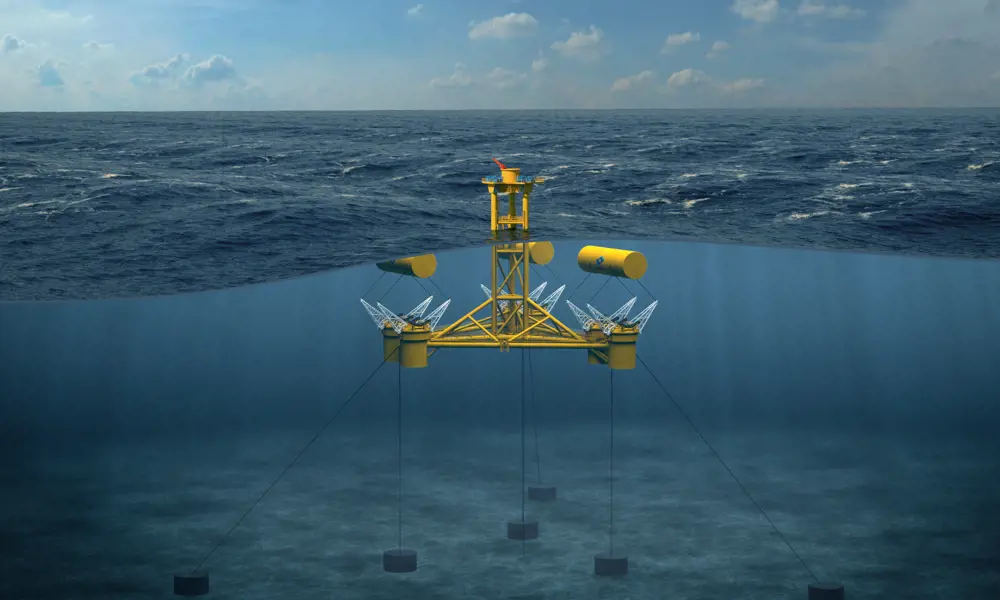

WaveSub harnesses the motion of sub-surface water particles © Marine Power Systems

WaveSub electricity generation from energetic waves

One example of a successful wave energy converter deployment involves WaveSub – one of a trio of devices manufactured by Swansea-based Marine Power Systems. This device is designed to produce utility-scale electricity generation from some of the most energetic wave climates on the planet. WaveSub comprises a tautly moored structure linked to three cylindrical wave energy absorbers, which captures and harnesses the motion of sub-surface water particles. Each WaveSub unit outputs a comparable level of power to a wind turbine and can be expanded into energy farms in much the same way. Captured energy is converted to grid-compliant electricity onboard the device, before being exported to the onshore electricity grid via subsea cables.

Since 2014, Marine Power Systems has regularly worked with COAST. Its research has included power capture investigations in directional seas, mooring layout trials, the development of multibody wave energy converters and the validation of numerical model simulations. Engineers can observe and validate complex problems, adjusting and refining their models within minutes. This has enabled them to increase the durability of motor waterproofing, while eliminating electrical interference and noise on signals – ensuring each WaveSub model is more robust and versatile than its predecessor.

COAST’s controllable basin has been key to the development of WaveSub and other offshore renewable energy hardware, but precise measuring equipment also plays a crucial role in subsequent analysis. A set of nine Qualysis cameras can track six degrees of freedom motion to 1.5 millimetre accuracy, while high-speed cameras deliver slow-motion replays of split-second events such as wave impacts or prototype damage. An extensive array of strain gauges, pressure transducers and accelerometers also contribute to a data acquisition pool that is processed by custom-written LabView software. Similarly, the wave and current generation software was supplied by the same firm who designed and built the basins, to harness the full potential of those 24 individually controlled paddles.

The Fall of Warness is a tidal test site located in the Orkney Islands, where marine currents reach speeds of four metres a second © Orkney Sky Cam, courtesy of EMEC

Tidal power as an alternative to wave power

While wave power is the most visible aspect of marine energy, tidal power offers an intriguing alternative – albeit with different challenges. Tidal streams are entirely predictable because the currents that cause them are formed in response to gravitational pull. For instance, the highest tidal ranges (rising and falling sea levels) are generated when the sun, moon and Earth are in line. This enables tidal power producers to calculate how much kinetic energy can be harnessed at any given point in time. Tides rise and fall twice a day, while many of the most powerful tidal streams occur where water is funnelled between islands, or between the coast and the seabed.

The Orkney Islands are ideally situated for harvesting tidal power, with tides flowing from the North Atlantic Ocean to the North Sea. As they pass through a narrow channel between the Westray and Stronsay Firths, marine currents reach speeds of almost eight knots (four metres per second). This is where Orkney-based European Marine Energy Centre (EMEC) established a grid-connected tidal test site, called the Fall of Warness. Seven cabled tidal test berths have been built across an area measuring around eight square kilometres, at depths ranging from 12 to 50 metres. Each cable feeds into a substation on the nearby island of Eday, with direct connections into the national grid and fibre-optic links to various switchgear and communications hardware.

The Fall of Warness has achieved several breakthroughs since it officially opened in 2007. The substation can redirect power produced by tidal testing devices to an electrolyser, making this the world’s first tidal-generated hydrogen extraction facility. Technology such as droppable cameras and hydraulic cutters reduces the need for divers to enter the water, where they can operate for a maximum of 20 minutes per day – while tides have stopped during daylight hours. Meanwhile, a purpose-built onshore weather station feeds into a supervisory, control and data acquisition system. Supported by a historian database, the system sends device information, environmental parameters and electrical performance to a data centre. Clients can monitor their equipment in real time, controlling it remotely while conducting detailed analysis on performance and stresses.

The SR2000 generated enough electricity to supply 7% of the Orkney Island’s electricity demand during several weeks while on test © Colin Keldie, courtesy of EMEC

Testing and refining tidal machines in the Orkney Islands

This test-and-refine process was recently harnessed by Orkney-based Orbital Marine Power, which tested its SR2000 tidal machine at the Fall of Warness. During a week of continuous operation, it generated more than 116 megawatt hours – enough to supply nearly 7% of the entire Orkney Islands’ electricity demand. The SR2000 was subsequently deployed in 2016 for a year of continuous operation, during which time its three gigawatt hours output exceeded the entire wave and tidal energy output in Scotland over the preceding 12 years.

The SR2000 has since been decommissioned in favour of a revised machine known as the Orbital O2, scheduled for completion at the end of 2020. Suitable for incorporation into large-scale arrays, each 73-metre floating superstructure has gullwing-style legs, which can be lifted above the water for maintenance or dropped below the surface for use. Each leg hosts a one megawatt steel turbine, whose 20-metre diameter creates the largest rotor area ever deployed on a single tidal generating platform. A 360-degree blade pitching control system allows these two counter-rotating turbines to capture power from both tidal directions without turning the machine to face the returning tide. The O2 can be reached by small boats at any tide, with most systems and components housed inside the floating superstructure to simplify access and inspection.

Blade Runners

🌪️ Offshore wind challenges and energy generation during a hurricane

The UK is the world leader in offshore wind power, which already generates 10% of the national electricity supply. Positioning turbines more than 40 kilometres offshore negates the aesthetic issues surrounding onshore wind farms, in turn permitting denser farms featuring blades measuring over 100 metres. These larger blades are less sensitive to wind speed variations than smaller onshore turbines, generating more predictable amounts of power. A single turbine can supply 12 megawatts of capacity, particularly since offshore wind speeds are usually much faster than over land. This is significant because power output increases as a cube of the prevailing wind speed: a turbine generates twice as much energy in a 25 kilometres an hour wind compared to 20 kilometres an hour.

Offshore wind energy poses significant challenges, some of which are shared with wave and tidal energy production. Extreme weather conditions can cause material damage, while it’s hard to anchor turbines in water deeper than 60 metres. However, the latter problem has been resolved at the world’s first floating wind turbine farm. Located 25 kilometres east of Peterhead, the appropriately named Scotland farm comprises five 254-metre turbines, anchored to the seabed by chains and thousands of tons of iron ore. These turbines collectively generate 30 megawatts of electricity, having achieved 65% of their maximum capacity during a hurricane while enduring eight-metre swells. That’s an extremely high output ratio – 100% energy generation would require completely consistent wind at an optimal speed.

Hywind is one of 30 offshore wind farms within the UK’s maritime waters. Installed capacity presently stands at over 8,000 megawatts, with 5,000 megawatts more under construction and a similar amount proposed for future developments. The offshore wind industry’s ambition is to meet a third of the UK’s electricity needs by 2030, producing 30 gigawatts of power, and it will rely heavily on British supply chains and expertise to achieve this target.

What is the future potential of the marine renewable energy sector?

Neil Kermode has been the Managing Director of EMEC since 2005. He believes the marine renewable energy sector offers huge potential, despite being a relatively youthful industry: “Around the world, pretty much every turbine and wave machine deployed is experimental to some degree. However, the more often it is done, the less experimental they become and the more commercial the offering becomes.” He argues that while practise makes perfect, it also makes things cheaper: “The more money that is invested in this technology, the more it can be demonstrated in real sea conditions, and the sooner it can be built out on a larger scale at competitive prices.” The benefits are compelling: “We know we have the energy in the tides around our shores, and we now know we have the technology to harvest that energy. The UK has the skills to develop, install, maintain and remove the equipment, and we’re going to need a lot more renewables to decarbonise our economy.”

Global improvements in air quality recorded during the COVID-19 lockdown have thrown into sharp focus the need to reduce our reliance on fossil fuels for energy production, particularly if the UK is to meet greenhouse gas emissions targets by 2050. Despite the considerable challenges of harnessing wave and tidal energy, the abundant and renewable nature of wave and tidal energy offers many benefits. Tidal and wave energy devices are less visually intrusive than wind turbines or solar PV farms, raising fewer issues surrounding planning and potentially having less of an impact on wildlife. Underpinned by the world-leading research and development currently being conducted across the UK, wave and tidal energy are likely to supply an ever-increasing proportion of domestic power generation in the coming decades.

***

This article has been adapted from "Turning the tide", which originally appeared in the print edition of Ingenia 83 (June 2020).

Contributors

Professor Deborah Greaves OBE is Head of School, Professor of Ocean Engineering and Director of the COAST (Coastal, Ocean and Sediment Transport) Laboratory at the University of Plymouth and is Director of the Supergen ORE Hub. In 2018, she was awarded an OBE for services to marine renewable energy, equalities and higher education

Neil Kermode is Managing Director of EMEC, where he has overseen the deployment of more marine energy technologies in the seas around Orkney than have been deployed at any other site in the world. Neil is a chartered engineer, Fellow of the Institution of Civil Engineers and a Chartered Environmentalist

Keep up-to-date with Ingenia for free

SubscribeRelated content

Energy

Algae-powered architecture

An apartment block in Hamburg in Germany has been built that uses microalgae placed within its façade to generate heat and biomass. Jan Wurm, an associate director at Arup, was one of the chief designers of the energy system. He talked about the concept, execution and results from the world’s first photobioreactor.

Digital hydraulics for wind energy and beyond

Research that has helped change the technology for harnessing wind energy has many other applications. The digital hydraulics system devised by Artemis Intelligent Power has received many accolades, the latest being the winner of the 2015 MacRobert Award.

New energy pioneers

London-based BBOXX supplies solar-powered battery boxes to customers in developing countries. Their remote monitoring and battery management system was one of the winners of the 2015 Bloomberg New Energy Finance Award.

Energy with connections

When Steve Holliday FREng moved from the oil industry into energy distribution, the sector was seen as staid. In reality, during his years at National Grid, the sector became increasingly important as the need to tackle climate change led to a transformation in the UK’s energy mix.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95