Accurate targeting of tumours

In the UK, one in every two people are likely to receive a cancer diagnosis at some point in their lives, and about 50% of them will require radiation therapy, which often successfully cures patients.

Radiotherapy works by targeting high-energy photon beams into tumours to destroy cancer cells. However, the radiation can also be harmful to healthy tissue, so healthcare professionals do their utmost to ensure that only the target area receives the dose. However, slight movements that patients naturally make during treatment can be almost impossible to detect, and these can lead to radiation damage to healthy tissue and potential long-term health problems.

Generally, in radiotherapy treatment, laser beams are used to help position the patient’s body before the treatment begins. Since several radiotherapy fractions (a series of treatment sessions that make up the entire course) are usually spread over a number of weeks, repeated accurate positioning is needed. To aid this, the patient is often given tattoo marks in several places so that the radiotherapist can determine the exact location of the tumour inside the body, based on a previously taken CT (computerised tomography) scan.

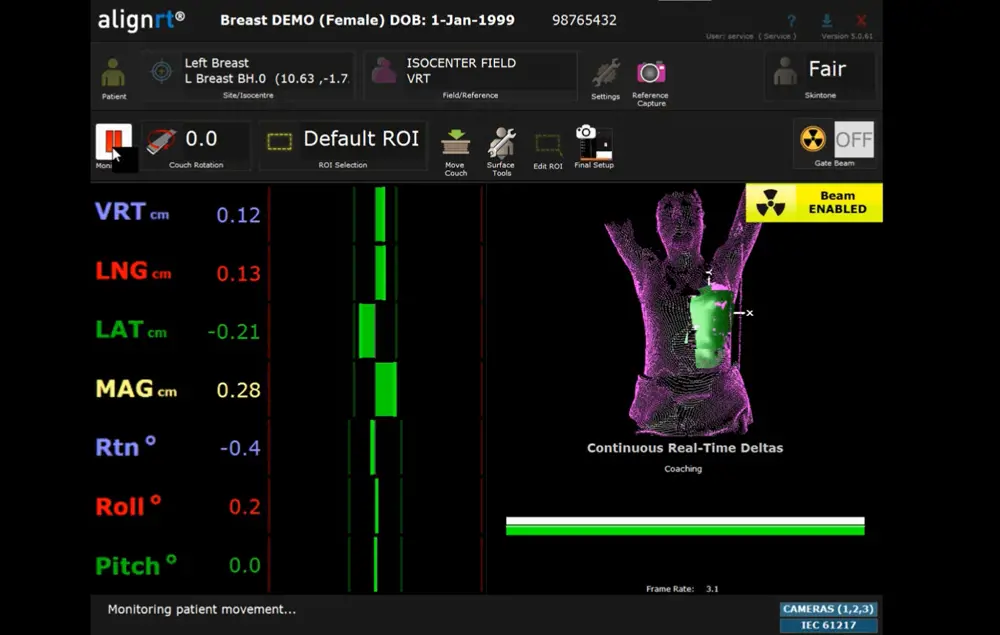

technology company Vision RT developed AlignRT, a completely non-contact system that continuously tracks the patient’s position in 3D before and during treatment with better than one millimetre accuracy

In order to ensure that patients can be set up precisely and radiotherapy is delivered as accurately as possible, technology company Vision RT developed AlignRT, a completely non-contact system that continuously tracks the patient’s position in 3D before and during treatment with better than one millimetre accuracy.

Creating a system

After graduating in electrical engineering from the University of Cambridge and completing a PhD in medical image processing at Imperial College London, Norman Smith, CEO of Vision RT, joined a startup that was developing stereoscopic imaging techniques for various applications. Stereoscopic imaging systems mimic human visual perception to see surroundings in three dimensions; they consist of two cameras positioned at a known distance from each other, in the same way that humans have two eyes to perceive depth.

During this period, Smith visited a few radiotherapy clinics and was surprised at how primitive some of the techniques for setup and monitoring were. He was confident that stereoscopic technology would be able to monitor not just a few tattoo marks, but the entire patient before and during radiotherapy treatment, and would also remove the need for the tattoo reference points on the body, which can remain a permanent reminder for patients of their cancer. While it was here that the idea for the AlignRT technology was born, the company that Smith worked for was not interested in developing the idea further.

A pseudorandom pattern is projected onto the patient’s body, which is picked up by the cameras and used to develop a 3D image of the patient’s surface area to precisely calculate their location during treatment

In 2001, Smith and co-founder and CTO Ivan Meir began operating as Vision RT from the attic of Smith’s parents-in-law’s house in North London. Gideon Hale, Vice-President Operations, joined the organisation 18 months later. The journey from vision to reality was not straightforward; at the time, there were no suitable ‘off-the-shelf’ stereoscopic camera systems available so they designed and engineered their own proprietary cameras, electronic hardware, processing software and user interface. Apart from the camera chips and lenses, all the system’s components are manufactured in the UK.

The system continuously monitors the patient surface using three separate 3D camera modules that are ceiling-mounted in the radiotherapy treatment room and view the treatment table from different angles. The camera modules also contain a projector that illuminates the patient’s body with a pseudorandom pattern on the surface of their body. This pattern is detected by the cameras and custom-written stereo-matching software to find corresponding points between pairs of calibrated stereo camera images. Through the process of triangulation, 3D coordinates are calculated for each set of 2D image points, which results in a 3D surface model comprising tens of thousands of points. The data from all 3D cameras is combined and the surface position is determined to sub-millimetric accuracy at a rate of 2 to 10 hertz (Hz) to precisely define the location of the patient as they undergo radiotherapy. This accurate surface map is then dynamically matched to a reference surface model derived from a CT image, and treatment is planned using this. This allows the location of the tumour, based on the patient’s body surface, to be tracked in all six degrees of freedom (the freedom of movement of a rigid body in a three-dimensional space) to ensure that the treatment is being delivered correctly.

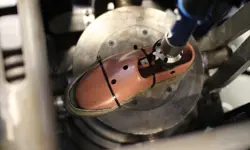

Each of the ceiling-mounted modules contain a projector and stereoscopic camera. These need to be precisely aligned and rigid

Accuracy, ease and comfort

In addition to real-time 3D mapping of the surface, the company has developed an easy-to-use interface software that, via a simple colour bar display, gives directions that allow the radiotherapy operator to position the patient faster and more accurately. Moreover, instead of relying on a human operator to stop the beam manually if the patient unexpectedly moves, the system senses the smallest of movements from the patient and automatically pauses radiation delivery, preventing damage to healthy tissue. A further benefit of this development is that it also removes the need for the patient to be held in place by a variety of invasive immobilisation frames or moulds, which were previously often used to restrict patient movement. Historically, treatment staff would also monitor the patient’s position and observe the tattooed marks via closed-circuit television from a neighbouring room. If the patient moved, they would manually stop the radiation beam, but this method is unable to pick up small movements and requires constant vigilance.

it also removes the need for the patient to be held in place by a variety of invasive immobilisation frames or moulds, which were previously often used to restrict patient movement

Accurate surface mapping requires the camera positions to be precisely aligned and rigid. This is helped by the fact that radiotherapy treatment rooms are usually solid concrete-walled and roofed structures, but it also means that the camera/projector modules must be rigid and thermally stable, which can be very difficult to achieve with an optical measurement system. The company solved this through careful mechanical design and an innovative thermal management solution, which ensures that the modules are operated at a controlled temperature.

Any detected motion must be synchronised to the treatment delivery machine (the linear accelerator), so the company has designed its own electronics modules for this and interfaced these, in collaboration with the different manufacturers, to their radiotherapy treatment delivery machines. The processing software, which at its core uses a mathematically complex and computationally challenging matching technique, must be both fast and accurate over the whole image to track any patient movement at high frame rates. The whole system calibration is checked daily and to do this the company has designed easy-to-use calibration phantoms that are mounted on the treatment couch, with built-in hardware and software consistency checks.

Confirmed results

The company’s first prototype was tested at the Royal Marsden Hospital, a cancer specialist centre, in 2002. This confirmed that the system could track an object to within a millimetre, and the following year, Vision RT submitted its data to the American Society of Radiation Therapy and Oncology (ASTRO), the world’s largest professional radiotherapy organisation. On acceptance of its paper for oral presentation, the company decided to attend ASTRO 2003 to exhibit its prototype technology at the associated industry trade show.

The company’s first prototype was tested at the Royal Marsden Hospital, a cancer specialist centre, in 2002

A chance encounter at the event between Smith and Meir and Dr George Chen, a professor at the Department of Radiation Oncology at Harvard Medical School and a leading authority in the field, initiated a productive relationship. Dr Chen had been attempting to develop something similar with MIT for three years, but had been unsuccessful. Within a year, Vision RT had installed a prototype system at Massachusetts General Hospital, Harvard Medical School’s largest teaching hospital and one of the world’s leading biomedical research facilities.

By 2005, two scientific papers were published in peer-reviewed journals; soon after, the company received clearance to market the technology in the US and the first units were sold, initially to leading academic institutions that were focused more on technical efficacy than usability. As Vision RT’s market expanded, feedback from more routine users complaining about the ergonomics of the system required the engineers to completely redesign the system’s user interface to make it very easy to operate. During subsequent years, a new and improved camera/projector system was developed, as well as an enhanced calibration technique to enable the exceptional accuracy that is required for radiosurgery treatment where the radiation beam is both narrower and of significantly higher intensity.

The software aids healthcare professionals in rapid positioning of patients prior to radiotherapy, and highlights any movement they make from their intended position during treatment

Exploring new areas

Vision RT long ago left behind the cramped attic of Smith’s parents-in-law’s home and its team of five has expanded to more than 150 people. Now, the technology is used in 70% of the top 50 cancer centres in the USA and in more than 30 countries around the world. The system is becoming a standard in radiotherapy treatment. The company has pioneered a new field of surface-guided radiotherapy treatment (SGRT) and has built up and supported a ‘SGRT community’, consisting of almost 1,000 healthcare professionals, which trains, shares and helps develop the technique and the AlignRT product.

The company has also signed a distribution agreement with Varian Medical Systems, the world’s largest manufacturer of radiotherapy treatment delivery systems, through which a Varian-branded version of the AlignRT 3D surface-imaging technology has become part of the company’s offering; it is incorporated into many of Varian’s radiotherapy systems.

The accuracy and rapid mapping of the system has enabled an advanced form of treatment for left-breast tumours

The accuracy and rapid mapping of the system has enabled an advanced form of treatment for left-breast tumours. Because of the closeness of the heart to these tumours, damage to cardiac blood supply is a common complication. However, if the patient takes a deep breath, this moves the heart away from the chest wall. By monitoring when the patient is holding their breath, the AlignRT technique can ensure that the radiation is only delivered to the tumour during this period and not to the heart. Using the simple alignment software that had already been designed to enable the radiographer to position the patient, Vision RT has produced a simple tablet-based bar graph display that the patient can use to ensure that they have taken a deep enough breath to move the chest wall, and hence the tumour and heart, into the right position for treatment.

By monitoring when the patient is holding their breath, the AlignRT technique can ensure that the radiation is only delivered to the tumour during this period and not to the heart

The treatment of left-breast cancer has been a success story; a recent clinical study in North Carolina showed that no patients who were treated with the guidance of AlignRT experienced damage to heart blood supply, in comparison to 27% in a previous study using traditional techniques.

With Vision RT having over 50 patents to date and its clinical evidence being evidenced in more than 60 peer-reviewed papers, it seems that the practice of SGRT can only go from strength to strength.

The author would also like to thank Professor David Delpy CBE FREng FRS for his help in putting together this article.

***

This article has been adapted from "Accurate targeting of tumours", which originally appeared in the print edition of Ingenia 73 (December 2017)

Contributors

Tereza Pultarova

Author

Dr Norman Smith is CEO and Co-Founder of Vision RT. He studied engineering at the University of Cambridge and holds an MSc and PhD in medical imaging from Imperial College London. Dr Smith is a Fellow of the Institution of Engineering and Technology and the Royal Academy of Engineering, and is named inventor on several patents.

Keep up-to-date with Ingenia for free

SubscribeRelated content

Health & medical

Kidney dialysis

Small haemodialysis machines have been developed that will allow more people to treat themselves at home. The SC+ system that has been developed is lighter, smaller and easier to use than existing machines.

Engineering polymath wins major award

The 2015 Queen Elizabeth Prize for Engineering has been awarded to the ground-breaking chemical engineer Dr Robert Langer FREng for his revolutionary advances and leadership in engineering at the interface between chemistry and medicine.

Blast mitigation and injury treatment

The Royal British Legion Centre for Blast Injury Studies is a world-renowned research facility based at Imperial College London. Its director, Professor Anthony Bull FREng, explains how a multidisciplinary team is helping protect, treat and rehabilitate people who are exposed to explosive forces.

Targeting cancers with magnetism

Cambridge-based Endomag has helped treat more than 6,000 breast cancer patients across 20 countries. The MacRobert finalist uses magnetic fields to power diagnostic and therapeutic devices. Find about the challenges that surround the development and acceptance of medical innovations.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95