Decarbonising the shipping industry

Did you know?

🤯 How many double decker buses??

- It’s estimated there are between 50,000 and 60,000 cargo ships worldwide

- More than 500 ships pass through the English Channel each day, travelling from the North Sea to the Atlantic Ocean and vice versa

- The world’s biggest container ships are longer than 33 double decker buses lined up end-to-end (too long to travel down the Panama Canal without getting stuck in its lock chambers)

Shipping lets us enjoy cotton from India, gadgets from South Korea and coffee from Brazil before we even leave the house each morning. The hundreds of components that make up your phone come from all over the world, meaning it’s clocked up thousands of miles on the open seas before you ever switch it on. Shipping makes modern life as we know it possible – not to mention a lot more convenient and comfortable.

It’s one of the least polluting means of transporting goods, as compared with air and road freight. Nevertheless, most of the world’s fleet burns fossil fuels. So, it is still a significant source of greenhouse gas emissions, responsible for about 3% of the world’s total. The ships that deliver goods to us also emit other pollutants that are harmful to human health and the environment, such as sulphur dioxide.

In accordance with the Paris Agreement, the International Maritime Organisation (IMO), the United Nations’ regulatory body for shipping, has called for a 50% reduction in the industry’s greenhouse gas emissions by 2050. To reach this target, engineers are working to make every part of shipping greener.

A sizable component of these efforts, and yet just one part of the decarbonisation puzzle, is ship propulsion. To reduce emissions while keeping the world’s ships moving, we need to decrease the amount of fuel we’re using, replace it with something that produces less or no carbon, or both. (See just how many cargo ships were moving around the world even back in 2012, in the dynamic map below created by Kiln and the UCL Energy Institute.)

All aboard: sizing up the challenge

Diesel engines still power the vast majority of shipping vessels today. They run on fossil fuels – typically heavy fuel oil, light fuel oil, or marine diesel oil. These are energy-dense fuels, so a little goes a long way. Although the efficiency of diesel engines has improved in the past half-century, and applying speed limits on ships can reduce emissions, more must be done to reach the IMO’s target. As such, many companies are considering alternative fuels, including liquefied natural gas (LNG), biofuels and emerging options such as ammonia, hydrogen and green methanol.

However, the transition to a low-carbon future in shipping will be challenging. Fossil fuels are relatively cheap, the industry as a whole already operates on fine margins, and being a global industry, there are many moving parts to consider. Just one example: ships must be able to refuel on their routes, so the bunkering (fuel supply) facilities that are available internationally will drive fleet operators’ decisions. To avoid disruption, change must be well-considered and gradual.

A ship at a bunkering facility © Shutterstock

“What we’re trying to do is replace a very cheap and a very effective energy carrier, which is a hard act to follow. And we have to do it at scale – enormous scale – and it has to be distributed across the UK and across the world,” says Tony Roskilly, chair of energy systems at Durham University’s department of engineering. “The scale-up is one of the biggest challenges.”

Roskilly heads the UK National Clean Maritime Research Hub. Established in September 2023, the UK-MaRes Hub’s goal is to accelerate decarbonisation in shipping and eliminate air pollution produced by marine activity, both at sea and at ports. It brings together 13 British universities as well as dozens of organisations from around the world, including shipping companies and fuel producers.

The UK shipping industry cannot be disentangled from international shipping, says Roskilly. “It’s an international activity that drives the whole economy.”

One of UK-MaRes Hub’s objectives is to research sustainable marine fuels and their safe use. These proposed alternative low- or zero-carbon fuels include hydrogen, ammonia and LNG (see ‘Sustainably transporting gas’, Ingenia 84).

However, with any of the fuel alternatives, it is crucial to ensure that we’re not reducing emissions from propulsion while increasing emissions elsewhere. This is important to consider in the whole lifecycle of any of the options. It includes production of the fuels themselves and extraction of any raw materials used, as well as the machinery required to store, transport and use the fuels.

With any of the fuel alternatives, it is crucial to ensure that we’re not reducing emissions from propulsion while increasing emissions elsewhere.

Making hydrogen and other fuels

❔ Grey, blue or green?

The most common way to produce hydrogen is currently the steam methane reforming (SMR) process. In SMR, steam and methane are reacted to separate out the hydrogen, which creates carbon dioxide as a side product (as well as trace amounts of carbon monoxide). This is called grey hydrogen.

To make the process carbon-free, chemical companies can capture the carbon as it is being made (in which case, the resulting gas is called blue hydrogen).

Alternatively, they can do away with SMR completely and produce hydrogen using water electrolysis (green hydrogen). Companies such as Ceres Power are developing electrolysers to do exactly this, which also work as fuel cells. Green hydrogen can then be used to make (green) ammonia and methanol – themselves promising shipping fuels.

Frontrunner future fuels

Hydrogen and fuels derived from it hold promise for zero-carbon propulsion.

Hydrogen can be mixed with other fuel sources and burned in combustion engines. It can also power fuel cells – an almost 200-year-old invention that enjoyed a resurgence during the space age, playing a role in taking astronauts to the Moon. Fuel cells combine hydrogen and oxygen to produce electrical and thermal energy, with both propelling the ship. The only exhaust is water. High-temperature fuel cells can be just as or even more efficient than diesel engines if the heat they put out is also used.

Although hydrogen produces no CO2 or sulphur oxide when used in an internal combustion engine or fuel cell, current methods for producing it at scale are not carbon-free (see ‘Making hydrogen and other fuels’). Furthermore, the infrastructure for hydrogen, including storage and transportation, doesn’t yet exist.

There are a few tricky challenges to address. For example, hydrogen is less energy-dense than conventional marine fuels – so you need a lot of it on board, at the expense of space for precious cargo. It’s also highly flammable, introducing the need for more safety measures. Finally, it must be stored at high pressures or low temperatures, and storage systems that do this are likely to be heavy, making vessels less fuel-efficient. As a result, some analysts think it’s best-off powering short-distance vessels.

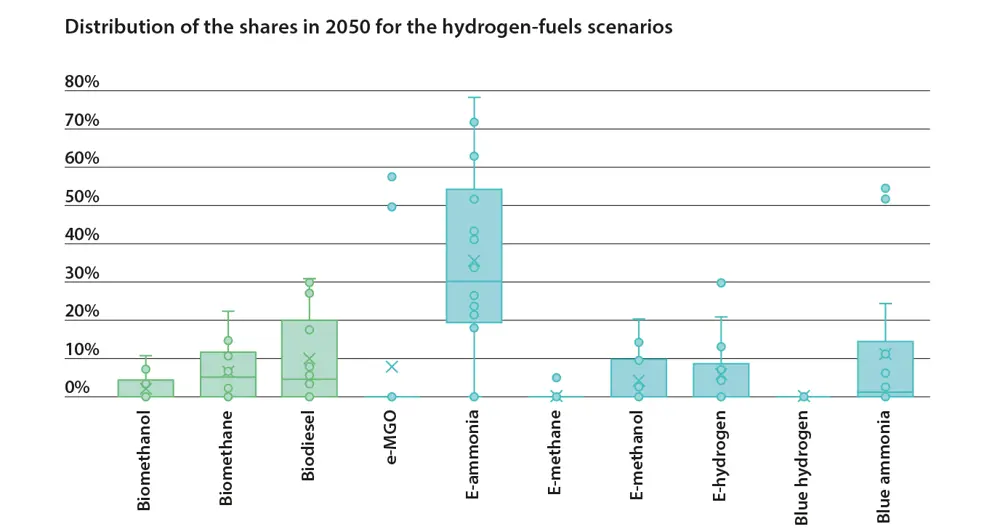

There are many different forecasts of the fuel mix for 2050, but many expect ammonia derived from hydrogen (e-ammonia) to be the most popular. While not discussed in detail in this article, biofuels are also expected to have a significant share. However, the maritime sector will be competing for this supply with the aviation industry. Adapted from The future of maritime fuels: What you need to know (Lloyd’s Register Maritime Decarbonisation Hub, 2023).

This may make a purely hydrogen propulsion method unviable for the time being, but engines that work with more than one fuel could help bridge the gap. Along with his team, Roskilly has been developing a combined system that can be fuel-flexible, meaning it can work with fuels other than hydrogen: “We’ve done a lot of work on hydrogen,” Roskilly says, “but there are other hydrogen carriers [substances that can store and transport hydrogen] that are of interest, particularly for the marine sector and other industry, such as ammonia, methanol, and a lot of other alternatives.”

This provides flexibility, as the fuel that will ultimately emerge dominant across the sector is still a big unknown. “The technology that we’ve developed has the advantage of being able to adapt to a new fuel source, so that when we’re going through this transition, we’re not reliant on hydrogen.”

Ammonia (NH3) is another alternative fuel being considered. Many consider it likely to become the long-term solution, as it is much easier to store and more energy-dense than hydrogen. It can be burned in diesel engines and gas turbines, and although it produces no CO2 on board, current methods for its production, which involve SMR and the Haber process, are not carbon-free. If it is to solve the decarbonisation problem, it will need to be made ‘green’ from green hydrogen.

Sustainable energy startup Amogy is exploring how ammonia made from green hydrogen can be harnessed in zero-carbon shipping.

Green methanol is another fuel that can be derived from green hydrogen. In September 2023, Maersk announced a startup, C2X, which aims to produce 3 million tonnes of green methanol per year by 2030.

As a fuel, LNG generally produces about 25% less carbon emissions than conventional fuels, and no sulphur oxides. Many companies have been adopting LNG, which can be used with the fuel systems currently in use.

However, the main component of LNG is methane, itself a greenhouse gas 21 times more potent than carbon dioxide, and so it must be handled with care. Methane slip – where the gas escapes into the atmosphere during refuelling or through engine systems – may override any benefits of using the less carbon-heavy LNG as compared with heavy fuel oil. Companies including Wärtsilä and MAN Energy Solutions are working on engines aimed at reducing methane slip.

Many of the items around you and their components will have spent some time in a shipping container © Teon Yuhong / Unsplash

The return of wind

🌬️ How an old technology could give fuel efficiency a huge boost...

The shipping industry is also looking at renewable sources of energy, such as wind. When used in combination with fuel propulsion, wind can reduce the amount of fuel needed and so take a good bite out of the greenhouse gas emissions it produces.

Towards this goal, marine engineering firm BAR Technologies has created the WindWing, born out of knowledge developed racing yachts at the America’s Cup, the ‘Formula One of the Sea’.

WindWings produce thrust in the same way wings produce lift for an aircraft. Each wing has three separate elements so that its shape can change, making it possible to control the amount of thrust produced. They are made primarily of steel, with an outer surface of fibre-reinforced plastic. They’re made in the same way as wind turbine blades and built in a wind turbine factory.

WindWings set sail on its maiden voyage atop a Cargill vessel last summer. BAR Technologies had previously worked with the company, which operates a fleet of about 650 vessels and in 2021 moved more than 200 million tons of cargo, to improve its fleet’s efficiency.

Depending on wind speed and direction, each WindWing is estimated to reduce fuel consumption by 1.5 tonnes per day. So, while modern wind power systems can provide some assistance to fuel propulsion, fully powering a ship is out of the question for now.

The Berge Olympus has four WindWings, saving 6 tonnes of fuel per day © BAR Technologies

A green future for shipping?

Developing alternative fuels and greener methods of propulsion is just one element of decarbonising the shipping industry. The entire lifecycle must be considered to secure a sustainable future for the sector.

As an industry, shipping covers a range of activities, encompassing everything from ferries that go back and forth across relatively short distances, to large container ships that go on weeks-long voyages across oceans. No one solution can apply to all of these activities.

“The solutions will be different for different sorts of vessels and different classes of vessels,” says Simon Schofield, Chief Technology Officer at BAR Technologies, which has developed the WindWing to harness wind in ship propulsion (see ‘The return of wind’).

“It’s not going to be a single golden bullet that solves the problem. It’s going to be a combination of lot of different technologies coming together.”

The complexity of the challenge demands expertise from a wide range of disciplines, so it’s important that engineers, academics and those in industry work together. Indeed, this was the thinking behind UK-MaRes Hub.

“It’s crucial that we bring all of the skills and disciplines together to work on this complex system,” says Roskilly. “In the vast majority of research programmes that I’m working on, we incorporate colleagues from geography, anthropology, business... all different disciplines.”

“We have to think of this as a transition. We’re talking about global shipping, thousands and thousands of ships moving and delivering 80 plus percent of everything we eat, touch, wear.”

Professor Tony Roskilly, Director of the UK National Clean Maritime Research Hub (UK-MaRes)

The transition to net zero will take time – diesel engines dominate the shipping industry and have done for decades. It’s a well-established technology where repairs and spare parts are relatively easy to come by, and that engineers the world over understand. For many of the potential future fuels, the infrastructure needs to change before wider adoption, from engines to storage. That won’t happen overnight.

"We have to think of this as a transition,” says Roskilly. “We’re talking about global shipping, thousands and thousands of ships moving and delivering 80 plus percent of everything we eat, touch, wear.”

However, at least one recent development has shown that change is possible. Use of heavy fuel oil fell dramatically after the IMO imposed a limit on sulphur content in fuel oil. Many shipping companies based in the Nordics aim to become carbon neutral by 2050, which would surpass the IMO’s deadline. This implies that if conditions are right, and there is the will and the means, transformation in the sector can happen. A comforting thought when after a long day, having returned home on the bus (from Germany), you lay your head down on your pillow (from Sweden), and turn off the light (from China).

Contributors

Tony Roskilly is Professor of Energy Systems at Durham University, a Co-Director of Durham Energy Institute, and the Director of the UK National Clean Maritime Research Hub. He is a Fellow of the Institute of Marine Engineering, Science and Technology and a member of the Department of Transport College of Experts.

Simon Schofield is the chief technology officer of BAR Technologies, leads the technical teams and has been instrumental in developing the business direction of the company. Simon has spent over 20 years at the forefront of the technical development of grand prix racing yacht development. His wide-ranging experience includes multiple Americas Cups Campaigns, Volvo Ocean Races and Offshore and Inshore Grand Prix Race yachts.

In between Cup cycles Simon also achieved commercial success and was a partner in his own design business prior to working alongside Sir Ben Ainslie during the 35th America’s Cup. Simon was head of design and engineering for Ben Ainslie Racing, the British entry before jointly founding BAR Technologies with Martin Whitmarsh (now chairman).

Leonie Mercedes is a freelance writer based in London.

Keep up-to-date with Ingenia for free

SubscribeRelated content

Maritime & naval

Modelling ships in danger

Stricken ships in danger of breaking up, sinking, capsizing or losing their fuel or cargo need expert help to be rescued. Lloyd’s Register’s Ship Emergency Response Service (SERS) was set up to provide this support.

Quieter, more efficient propellers

Göran Grunditz, Manager of the Rolls-Royce Hydrodynamics Research Centre, explains the challenges when reducing noise from marine propellers for passengers onboard ships and for military vessels that seek to avoid detection, while maintaining a high thrust per input power and maximising efficiency.

Building Britain's biggest warships

The 1998 Strategic Defence Review called for the UK Armed Forces to be able to operate with more agility to confront situations on a worldwide basis and resulted in the requirement for two new Queen Elizabeth Class aircraft carriers, HMS Queen Elizabeth and HMS Prince of Wales, one of the UK's largest engineering projects.

Against the tide

The Royal National Lifeboat Institution introduced the Shannon class all-weather lifeboat in 2014, which uses cutting-edge technology, is faster and more manoeuvrable than existing vessels, and has a quicker and safer launch and recovery system. Read about the design and production of the lifeboat.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95