Thin and flexible but tough protection

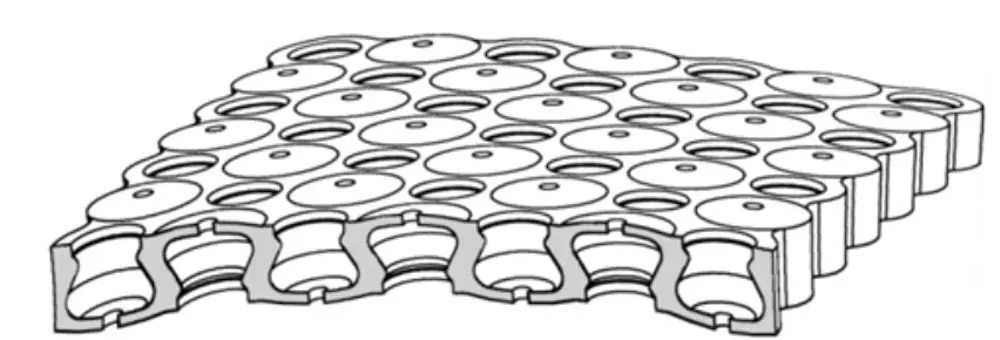

Armourgel’s internal auxetic structure, which compresses and absorbs energy upon impact

Dr Dan Plant, then an engineering PhD student at Imperial College London, had the idea for Armourgel when he was racing motorbikes in Europe; it was far too hot for traditional motorcycling protective clothing and he needed a solution.

He began working on a new protective material by testing combinations and layers of different composites and using softer, more flexible resins, instead of the hard resins covered in multiple textile layers that protective clothing is traditionally made from. His team tested around 2,500 different compositions before finding the optimum combination that resulted in a light, thin, yet protective material, made from a synergy of a thickening polymer and an auxetic geometry.

This resulted in a material that combines the properties of a smart material with a clever internal geometry

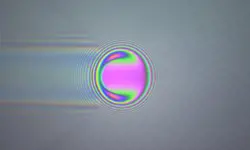

This resulted in a material that combines the properties of a smart material with a clever internal geometry. The smart material, shear-thickening polymer, is soft and flexible, but absorbs shock and stiffens momentarily on impact. The material has a different response at different strain rates. When moved slowly it is soft and flexible, allowing it to move with the musculature of the body, but when it is subjected to impact it momentarily stiffens, absorbing energy and spreading the load.

The technology was first used in clothing for extreme sportswear. Dr Plant applied for and was awarded a Royal Academy of Engineering Enterprise Fellowship, which provided him with funding and mentoring from an engineering leader to help him develop and commercialise Armourgel for the medical market. The first development he focused on was a preventative measure for hip fractures after learning that these injuries account for 15% of orthopaedic hospital beds, costing the NHS £2.4 billion a year.

The first development he focused on was a preventative measure for hip fractures after learning that these injuries account for 15% of orthopaedic hospital beds, costing the NHS £2.4 billion a year

In order to use the technology to create a preventative device for hip fractures, the team needed to design something that could provide the necessary protection, but was also comfortable enough to be worn on a daily basis under regular clothing. As Armourgel has high energy-absorption levels, it can be used in a much thinner layer and integrated within garments.

As the company continues to expand into new markets and applications, the technology will be used in helmets for use in areas such as the military, racing and sports. Dr Plant hopes to produce Armourgel products to sell directly to consumers and set up an advanced manufacturing centre in the UK.

***

This article has been adapted from "Thin and flexible but tough protection", which originally appeared in the print edition of Ingenia 70 (March 2017).

Keep up-to-date with Ingenia for free

SubscribeRelated content

Materials

Aerogels

Among some of the lightest known solid materials, aerogels, formed by removing liquid from gels, have many uses ranging from catalysts and sensors, to being used on NASA missions.

Recycling household waste

The percentage of waste recycled in the UK has risen rapidly over the past 20 years, thanks to breakthroughs in the way waste is processed. Find out about what happens to household waste and recent technological developments in the UK.

Diamond technology: beyond hardness

Diamond is being used in an increasing variety of industrial and technological applications, due to other properties in addition to its hardness. The UK is home to a wide range of diamond research, development and synthetic diamond production activities.

A lot more than lubrication

The control of friction and wear in mechanical systems by lubrication and surface engineering has led to safer, faster transport as well as medical innovations. Ian Hutchings FREng, GKN Professor of Manufacturing Engineering at the University of Cambridge, highlights the progress and some failures of the important discipline of tribology.

Other content from Ingenia

Quick read

- Environment & sustainability

- Opinion

A young engineer’s perspective on the good, the bad and the ugly of COP27

- Environment & sustainability

- Issue 95

How do we pay for net zero technologies?

Quick read

- Transport

- Mechanical

- How I got here

Electrifying trains and STEMAZING outreach

- Civil & structural

- Environment & sustainability

- Issue 95